Mastering Tensile Pull Test Techniques

Working as a materials engineer for over a decade, I’ve conducted numerous tests to understand how materials respond to stress. These tests are extremely crucial for ensuring products are of high quality and safe in various industries. Therefore, in this article, I will discuss five primary reasons why such tests are widely used, and I will also share my personal insights and experiences.

1. Accurate Measurement of Material Strength

2. Quality Control in Manufacturing Processes

3. Material Selection and Development

4. Research and Development of New Materials

5. Standardization and Certification

1. Accurate Measurement of Material Strength

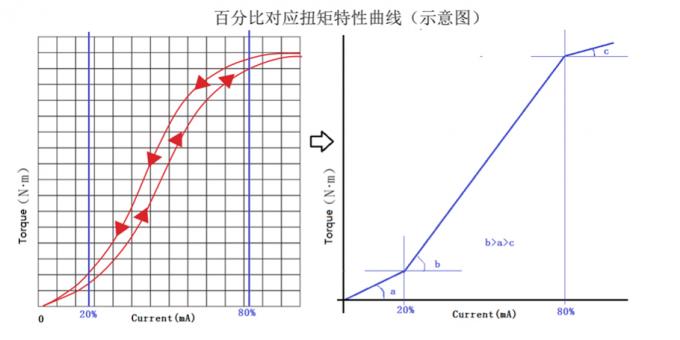

The main thing we do in a tensile pull test is to figure out how strong a material is. We gently pull on a sample until it Fractures to see how much Force it can withstand.

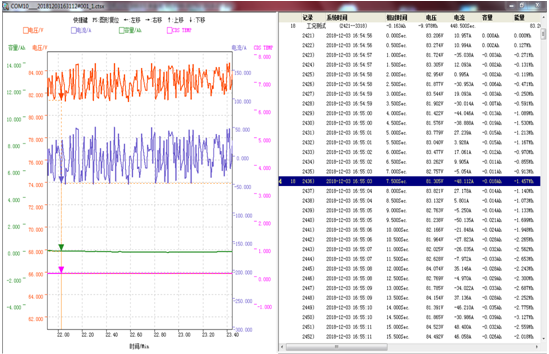

Looking at the curve from the test, we can tell how much force the material can take Up to the point of breakage, and Additional interesting information about it. This info is Extremely helpful for Designers to make sure their Items can handle Their intended purpose.

2. Quality Control in Manufacturing Processes

These exams are a big deal in making sure materials are Up to standard and meet all the standards. When you’re making stuff, materials get all kinds of Tensions and compressions.

Routine examinations help us Identify any issues with materials and Correct them so we can Maintain high quality. This helps in reducing defects and improving the overall performance of the Items.

3. Material Selection and Development

Another significant factor for these examinations is assisting engineers select the appropriate materials and create new ones. Engineers must consider how various materials respond to stress to determine the most suitable one for the task. These examinations give engineers all the information they require to make informed decisions regarding materials.

4. Research and Development of New Materials

Material scientists use these examinations to observe how novel materials behave under varying circumstances. Examining how these materials respond to stress facilitates researchers to understand about their characteristics and their potential applications. This aids scientists in creating new materials that are superior and have a longer lifespan.

5. Standardization and Certification

It is crucial to have norms in material assessment. Several include various norms for these examinations, like American Society for Testing and Materials and International Organization for Standardization.

Adhering to these guidelines guarantees the results of the tests are reliable and can be contrasted irrespective of where they are conducted. And to to add to it, Several include inspectors to ensure the test facilities are satisfactory, thus leading to the results of the tests more credible.