Mastering Tensile Strength in Steel

So, when we talk about figuring out this material’s quality, a extremely significant test is this tensile strength test. This test not only tells us magnitude of force a piece of this material can take at failure, but it also gives us indications of this strength it really is overall. In this article, we’re going to get an in-depth look at details of tensile strength testing for this material, and look at some important terms and methods that this material industry professionals should know.

Material Properties

Material qualities are this foundation of material behavior under various circumstances. For this material, like tensile yield point stress, ultimate tensile strength, and elongation are key components of its material characteristics.

Tensile strength is the force a material can withstand before Permanente Verformung occurs, while Tensile strength is the highest force it can handle before breaking. Stretching capacity is how much a material can stretch before it fails and breaks. These characteristics are extremely crucial for determining if steel is suitable for the task.

Test Methodology

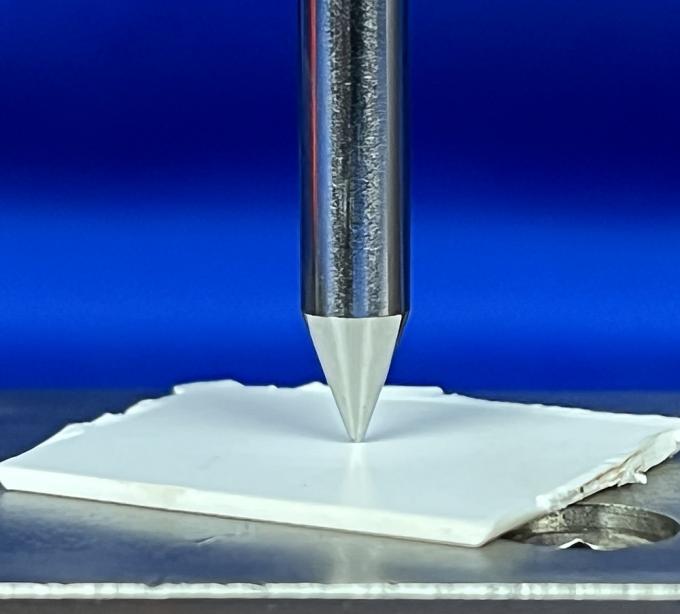

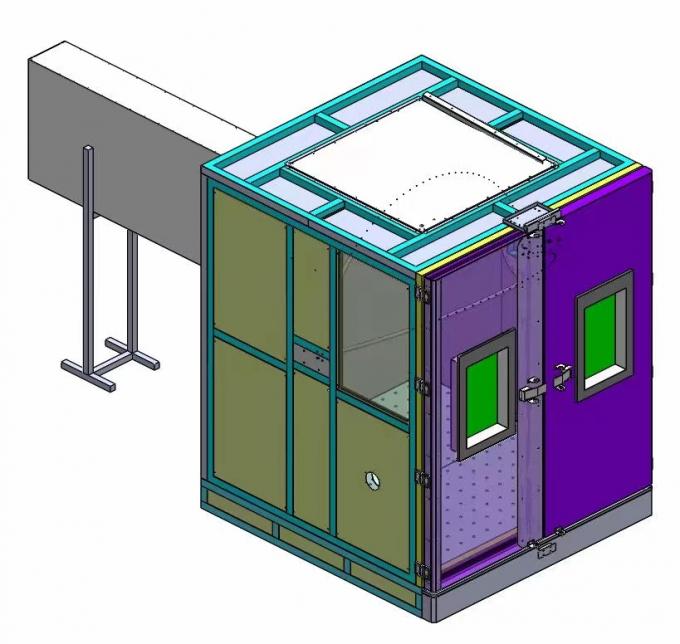

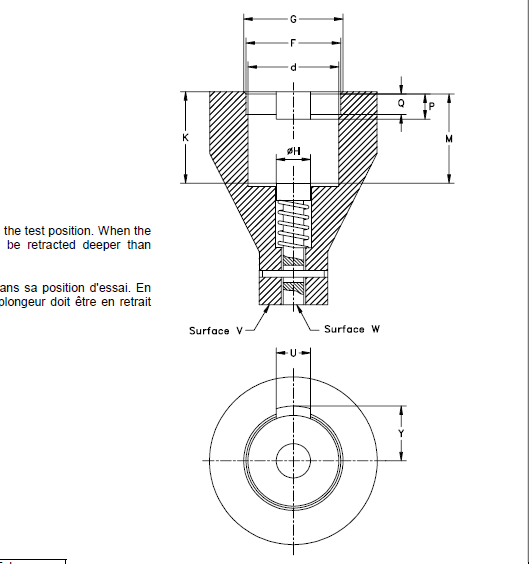

You do the tensile testing with this large equipment called a all-purpose testing machine, or Universal Testing Machine. You put the steel specimen into the equipment, and then you Continue to stretch it until it fractures.

As it is breaking, the data the machine gathers information like the amount of force it applies, the degree of its stretch, and the stress on it. All the data the data the machine gathers is utilized to calculate the material’s Tensile strength, Tensile strength, and Stretching capacity. It is essential to ensure the testing is conducted correctly so that you will rely on the outcomes.

Standardization

Withwithin the steel sector, ensuring consistency with standards is extremely crucial for ensuring test consistency and are comparable. There are these international and national standards, such as ASTM, ISO, and DIN, which provide guidelines for conducting the tests.

These standards spell out what to do during the test, what the sample should look like, and the kind of equipment you need. By adhering to these standards ensures the accuracy of the test results are reliable and are comparable anywhere.

Applications

This test is significant Withwithin the steel sector for assessing the quality of steel products. It enables manufacturers to determine whether their steel is suitable for applications such as construction, vehicles, or aircrafts.

Determining the steel’s tensile strength facilitates engineers in constructing structures that are secure, have a long lifespan, and perform effectively. Furthermore, the test can reveal any defects in the steel so we can improve our manufacturing process.

Conclusion

Bottom line, the tensile strength assessment is a super important tool for evaluating steel quality and functionality. When you understand terminology and how to perform this test, you can gain substantial knowledge about the behavior of steel and make informed decisions in the steel industry.