Mastering Tensile Testing: Insights from a Video Pro

Hey, everyone in the materials science and material engineering crowd! So, today we’re examining these cool tensile testers. I saw a video about them the other day and thought it was rather interesting. We’re going to dive into the top 5 key things to understand about these machines and learn some interesting facts while we’re at it.

Number two: why tensile testing is super important when you’re picking materials for a project.

Number three: all the cool new stuff that’s happening in the world of tensile testing machines.

Number four: how tensile testing helps keep things quality controlled in manufacturing.

And finally, number five: what’s coming up in the future of tensile testing.

Number one: the basics of tensile testing. Ever wonder what happens when you stretch a material to breaking point?

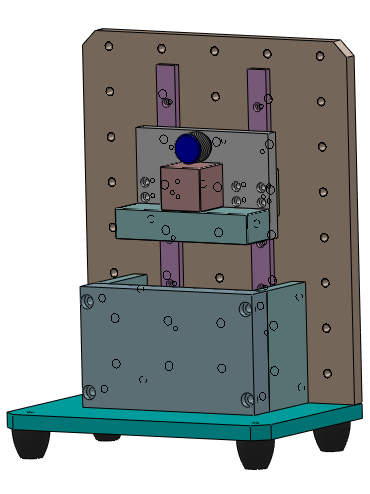

Ever think about what happens when you stretch out a material to see how strong it is? We’re going to talk about the basics of tensile property testing. It’s all about the gear and the science behind it. Remember when I first saw a tensile property test equipment? It was like a mini science demonstration.

The machine uses a applied force to stretch the sample until it breaks. By looking at the engineering stress-strain curve, we can learn a lot about the material—like how strong it is and how it stretches Until failure.

Number two: why tensile testing is super important when you’re picking materials for a project.

Choosing the ideal material for the work isn’t easy. That’s where These evaluations come in.

We stretch the materials to see which ones are right for the task. I’ve been involved in a number of projects where picking the correct material was crucial, and These evaluations have been super helpful in making good choices. Like, when we’re creating something that’s under significant stress, we need a material that is very strong and won’t fatigue easily.

Number three: all the cool new stuff that’s happening in the world of tensile testing machines.

Technology is improving, and and so too are these testing machines. The latest machines are even more accurate, faster, and more user-friendly.

I watched a video the other day that showed some very exciting new features, like auto-testing and advanced data analysis tools. These updates speed up the testing process and provide us with improved information.

Number four: how tensile testing helps keep things quality controlled in manufacturing.

Keeping materials and items quality-assurance is super important in lots of sectors. Tensile testing is crucial because it finds any issues or weak detects in the materials.

I’ve seen how one test can detect aspects that could cause issues, making for better items and safer stuff. Regular testing helps factories keep their items up to snuff and follow the rules.

And finally, number five: what’s coming up in the future of tensile testing.

Tensile testing is always developing, with new ways and tech coming out all the time. I think the future is going to be even cooler with stuff like artificial-intelligence and machine learning being used in material testing. These technologies could totally change how we do experiments, making them quicker and more-affordable.

If you want in relation to investigating addthe testing methodional inin relation tomation on tensile strength testing as well as how the testing method’s employed, I recommend investigating these materials.

<a href=