Mastering Velcro Strength Tests: My Journey

I’m a big fan of Component Assessment, and hook and loop fastener really gets my attention with its durability and utility it is in so many ways. I started checking out Velcro strength tests out of curiosity, and now I’m really into understanding the workings. I’m going to tell you about My explorations in Assessment hook and loop fastener Sturdiness. I’ll go over five primary aspects and give you my opinion on each one.

1. Standardized Testing Procedures

2. Material Selection and Preparation

4. Data Analysis and Interpretation

1. Standardized Testing Procedures

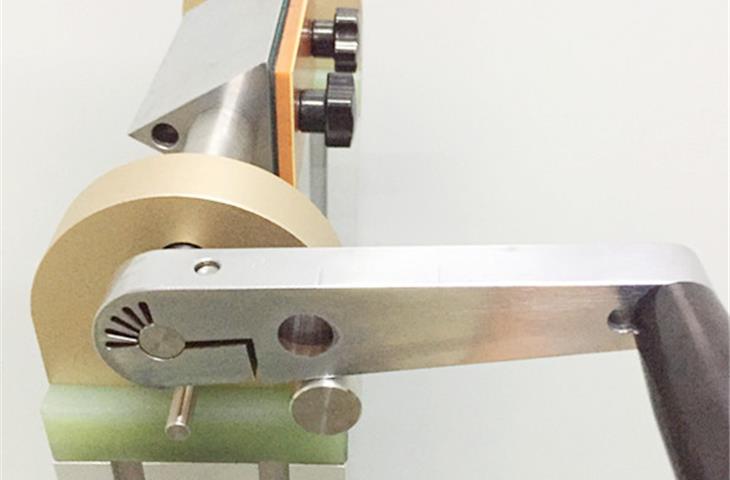

The main point in testing Velcro’s strength is having a set of guidelines to adhere to to ensure the tests are conducted uniformly. It’s primarily about having the proper equipment and following the instructions closely to obtain reliable results.

Like when I initially attempted doing a Velcro strength test, I took the time configuring the machine and ensuring I adhered to the plan. That experience instructed me how essential it is to be meticulous about the specifics and work systematically.

2. Material Selection and Preparation

Selecting the appropriate type of Velcro for the test is extremely important, is equally as important as conducting the test. Various applications require different types of sturdy Velcro with specific characteristics.

I have come to consider such as what the backing material is, how robust the adhesive part is, and how it is constructed. Like, when I test Velcro for outdoor use, I prioritize ensuring it is durable and withstand environmental conditions. It is necessary to cut the Velcro to the appropriate dimensions for the test and ensure it is clean with no dirt or debris on it which could compromise the results.

3. Tensile Testing Techniques

Stretching hook and loop fastener to its breaking point is a usual way to see its strength. I’ve observed and conducted the experiments where You pull the hook and loop fastener until it fractures.

It’s quite fascinating to observe how the hook and loop fastener acts as you’re pulling on it. You’ve got to apply an equal amount of tension and record the instant of its failure, nice and neat. Indeed it makes you come to realize its toughness and stretchy hook and loop fastener is, particularly as it is applied in high-stress environments.

4. Data Analysis and Interpretation

Once the testing is complete, examining the data is a big deal. You are focused on determining its breaking strength, its flexibility, and other such factors.

You can learn considerable by examining the data closely. It reveals valuable insights into how the hook and loop fastener behaves. For example, if the hook and loop fastener is more rigid, it may be suited for specific applications. Nevertheless, you must consider the purpose of its use as you’re examining the data.

5. Application and Innovation

Knowing how powerful Velcro is can lead to various clever new concepts. I’ve worked on tasks involving Velcro in lots of different things, from clothes to parts of cars.

Velcro is extremely adaptable and good for numerous items. Looking at various methods of testing and various substances, I’ve contributed to the creation of new ideas and made some current products better.

For those curious about exploring further into the world of Velcro strength testing, I recommend exploring resources such as <a href='https://www. Astm.

Org/Standards/D374. Pdf’>ASTM International’s D374 standard for evaluating adhesives and sealants, and SAE International’s standards for vehicle components. These resources provide a robust base for anyone looking to enrich their understanding in this field.