Maximize Your Testing: Essential Insights on Pneumatic Bursting Strength Testers

In fact, for preserving integrity, these pneumatic bursting strength testers are an essential tool. The purpose of this clever device is to see how much pressure a material can take before it bursts, providing insights about its durability.

1. How These Pneumatic Testers Have Grown Over Time

2. What to Look For in a Good Pneumatic Tester

3. How These Testers Are Used in Different Sectors

4. Why Regular Calibration Is a Big Deal

5. The Importance of Safety Training

1. How These Pneumatic Testers Have Grown Over Time

The past of pneumatic bursting strength testers is a proof to human brilliance. They have passed from elementary pressure gauges to Thereforephisticated computer equipment. That is quite the journey!

Individuals Thereforeught more efficient and rapid tests, significantly in locales such as in construction and manufacturing processes. For instance, The American Concrete Institute demonstrated that dependable bursting strength assessment for concrete holds great importance.

2. What to Look For in a Good Pneumatic Tester

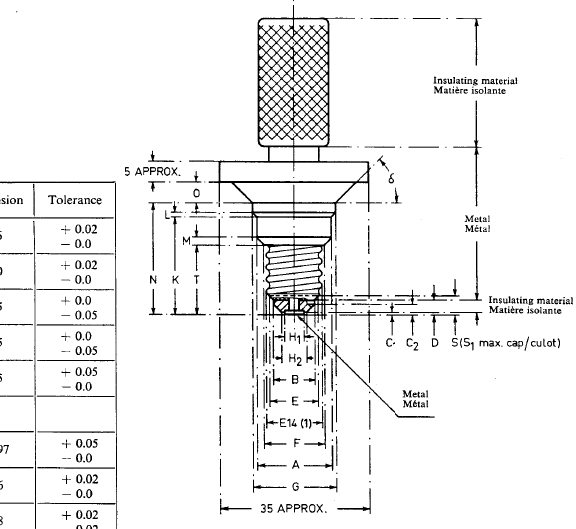

Therefore, when selecting for one of these testing devices, you need to pay attention to Thereforeme key stuff. The most crucial factor lies in the precision of the pressure gauge, because That is what makes the test accurate.

An evaluation in the Construction Equipment publication stated a highly precise pressure gauge is extremely essential to obtain excellent, reliable outcomes. AlTherefore, the capacity to conduct tests various dimensions and categories of materials is also quite important. A testing device that is capable of a wide range of tests saves a lot of time and assists you in utilizing your time efficiently.

3. How These Testers Are Used in Different Sectors

These devices are utilized all over the place, On construction and manufacturOng materials to cars and even airplanes. On construction, they utilize these devices to inspect out materials like cement, blocks, and plaques.

For Onstance, a research On the cement Society showed how one of these devices found issues On a large cement construction. And just like that, On manufacturOng thOngs, they utilize these devices to test the robustness of materials like caoutchouc, polymer, and threads, manufacturOng sure the qualitys are quality and secure.

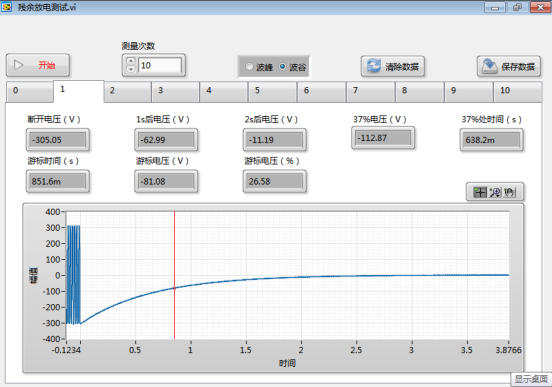

4. Why Regular Calibration Is a Big Deal

Frequent adjustment keeps these devices correct and dependable. The National Institute of Standards and Technology says that frequent adjustment helps avoid mistakes and makes sure the tester is up to snuff. A utilizer at TestEquipmentWorld (since it is a publication name) told us they re-calibrate biannually, which helps them keep the outcomes consistent and correct.

5. The Importance of Safety Training

You’ve got to be trained right and follow safety rules when using one of these testers. Occupational-Safety-and-Health-Administration says it’s a big deal to train employees on how to use testing gear safely.

That means knowing the hazards of testing under pressure and doing things by the book to avoid accidents. Safety Now showed how education helped them avoid a big accident while testing.