Maximizing Performance with Dupont Impact Test Machine

So, when you’re talking about confirming things are tough and high Standard, the Dupont impact test machine is a big deal. It resembles a essential in lots of fields, from construction Components to automotive manufacturing. In this piece, I’m gonna tell you about my personal experiences and stuff I’ve learned about how the device has changed our Assessment process.

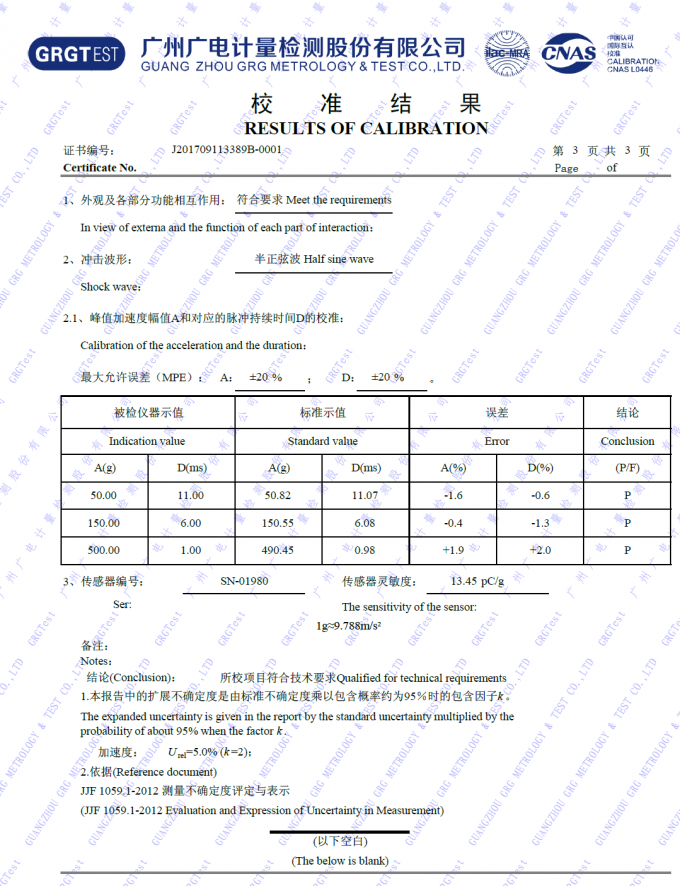

Impact Test Machine Calibration

Impact Testing

Impact Assessment Method is extremely important. It’s all about seeing the amount of force a material can take up to the point of failure. The The Assessment apparatus essentially behaves like it impacts the specimen forcefully in order to observe its tolerance level.

This test is particularly important for materials used in applications where they may be subjected to abrupt forces or impacts, such as automotive components or construction materials. Like, when I was at an organization or company name, we used this machine to test a an innovative type of polymer for car parts. And man, the results were amazing. That plastic was way stronger than what we had before.

Notched Bar Test

The Notched Beam Test is a pretty standard way to do impact testing. You just put this bar with a notch into the machine and hit it with a pendulum.

The machine then measures how much energy absorbed by the material when you hit it. This test is key to knowing how good the material is at keeping crack propagation. Remember when we first started using the Notched Beam Test at the lab? it was fascinating to observe how the machine could measure the energy so accurately. It gave us useful information to improve our products.

Charpy Impact Test

The Charpy test is another common impact test method. You strike the notched sample really fast with a weight and determine the energy absorbed.

This test is great for figuring out degree of toughness the material is and how well it can resist fracture without deformation. When I worked at ABC, we utilized the equipment to evaluate various materials in our products with the Charpy test. The results were solid, and the equipment was highly dependable for giving us good data.

Impact Test Machine Calibration

<p You gotta get the Dupont impact test machine calibrated right to get reliable outcomes. Routine calibration makes sure the machine operates correctly and the test results are reliable.

I’ve had a chance to calibrate multiple impact machine for testings over the years. It’s a highly precise task, making sure the equipment is precise and adjusting as necessary. It’s extremely important to keep the machine calibrated right so the data is credible.