Navigating the World of Rapid Temperature Change Chambers

You know, quick temperatureerature shift enclosures, or what some individuals refer to environmental testing enclosures, they’re super critical in lots of sectors. Those enclosures are designed for really subject substances and goods with quick and severe temperatureerature shifts, kind of like subjecting them to real life experiments.

1. High Precision and Stability

3. Versatility and Scalability

Whether or not it’s aeronautical components, healthcare equipment, or automotivemotive components, those enclosures are a major importance because they aid in testing for sturdiness, dependability, and operation. In this aspect, I am going to explore five key requirements for those quick temperature enclosures, discussing some information I have gained knowledge through the time.

1. High Precision and Stability

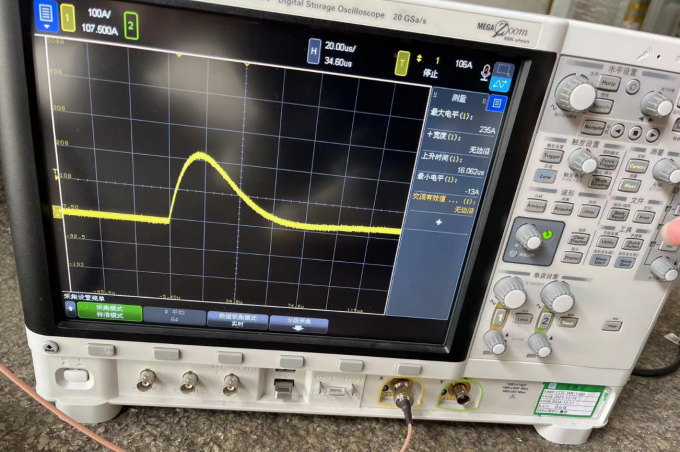

These systems have to be super precise and stable so the tests are accurate. These systems are fitted with high-tech temperature regulation systems that can quickly alter the ambient temperature to mimic varied climatic conditions.

Regulating the temperature extremely tightly is crucial because a small deviation can compromise the test. Consider the aerospace industry, for instance, components must withstand extreme temperature variations to ensure reliability in the atmospheric environment.

2. Safety and Reliability

Considering the dangers of rapid temperature fluctuations, ensuring These systems are safe and reliable is super important. Rapid temperature change chambers should be engineered with strong safety mechanisms to safeguard the instruments and equipment and the operators of the equipment.

Things such as urgent stop buttons, temporary alarms, and pressure release valves help ensure safety. I have observed reliable enclosures save a great deal of time and money by preventing accidents and reducing downtime significantly.

3. Versatility and Scalability

As technology improves, we’re seeing a big need for These enclosures to become highly versatile and capable of evolving with the progression of time. These enclosures need to fit Varied dimensions and categories of objects, From minuscule electronic components to substantial industrial equipment.

And they need to become able to Improve and increase capabilities, so they can keep up with shifting testing requirements. Take the Medical device sector, for example, These enclosures need to become able to test everything from little Diagnostics tools to Large medical equipment.

4. Energy Efficiency

Energy-saving efficiency is very important in the creation of these chambers. As people become more environmentally aware, manufacturers are developing making these chambers consume less energy but continue to function effectively.

In this manner, it reduces expenses and diminishes the chamber’s environmental impact. I have observed that energy-saving chambers can significantly reduce of the testing process, making them available for a wider audience for a wider audience.

5. User-Friendly Interface

And finally, an easy-to-use interface is extremely important for these quick temperature chambers. It should be possible for people to understand the controls and configure tests without needing to undergo extensive training.

This implies having clear interfaces, intuitive menus, simple programming options. Based on my observations, an effective design streamlines the process, reduces errors, and provides more trustworthy test outcomes.