Optimizing Sponge Strength: A Deep Dive into OEM Tensile Testers

You know, when we’re talking about maintaining wet cleaning sponges in good condition, those expensive testing devices are a big deal. These advanced devices are all concerned with determining the strength of wet cleaning sponges, which really matters for their longevity. We’re going to explore five interesting aspects about these wet cleaning sponge devices, telling anecdotes, giving you the news, and including expert insights for good measure.

First up: Why do we care about how strong sponges are?

2. Types of OEM Sponge Tensile Strength Testers

Next: The good stuff about these testers—why should you use ’em?

Now, let’s chat about the hurdles: What can go wrong when you’re testing?

And finally, we’ll peek into the future: What’s next for these testers?

First up: Why do we care about how strong sponges are?

The power of a sponge is a big sign of how good it is. If a sponge is extraordinarily strong, it can cope with much without wear and tear, so it lasts longer.

This is especially key in automotive environments, where sponges are used to clean and absorb stuff. For example, a study by some intelligent individuals showed that sponges that can withstand greater pressure last significantly longer than ones that can’t.

2. Types of OEM Sponge Tensile Strength Testers

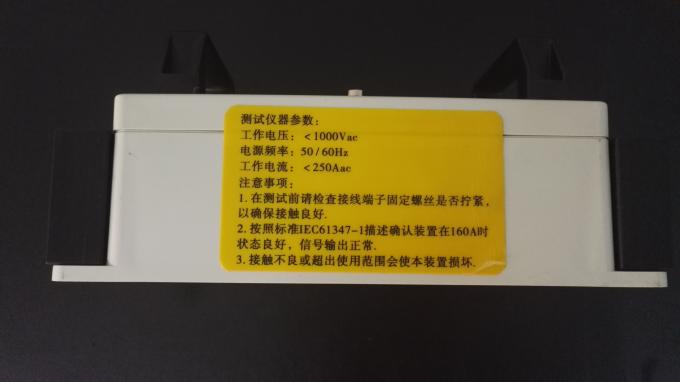

There are lots of different types of these testing equipment out there, each with their own unique features. Some of the most common includes types the digital tensile testing machine, the mechanical tensile testing machine, and the hydraulic tensile testing machine.

Every kind has its own benefits and is most effective for different kinds of tests. Like, if you’ve got a extremely durable sponge, you’d want to utilize a tester that can exert strong force, like a hydraulic tester.

Next: The good stuff about these testers—why should you use ’em?

Employing these testing devices can be highly beneficial. They are precise, fast, and enhance efficiency. They complete the task fast and give you precise figures, so companies can make more informed decisions about their products. For instance, a case study by a prominent sponge manufacturer demonstrated that utilizing an OEM tensile strength tester enabled them to cut down on their testing time by forty percent and enhance their product quality by twenty percent.

Now, let’s chat about the hurdles: What can go wrong when you’re testing?

You must examine, of course, however it’s not entirely straightforward. The key consists of maintaining the testing consistent and accurate.

This implies making proper care of the devices. Additionally, you need to choose the correct method to test and the appropriate sample size to obtain dependable outcomes. For instance, a research conducted by some knowledgeable testers proved that that it is necessary to utilize the correct testing approach to achieve favorable outcomes.

And finally, we’ll peek into the future: What’s next for these testers?

As we look ahead, technology will enhance these testing devices even more advanced, and there will be a growing demand for sponges that are environmentally friendly. As more companies strive to produce eco-friendly products, they will require testing sponges that are also environmentally conscious.

So, they’ll need to make new ways and tools to test these green sponges right. As a recent article mentioned that incorporating intelligent devices in testing will be a significant trend in the near future.