Optimizing Your Humidity Test Chamber Needs

So, When discussing ensuring items are exceptionally reliable and of high quality in various sectors, a humidity test chamber is essential equipment. Us get it, us operate in providing humidity testing chambers, and us understand how important it is to fulfill our clientele’ needs, irrespective of circumstances. In this article, us will explore five key issues regarding providers of humidity testing chambers. Us’ll give you some valuable knowledge and useful demonstrations to guarantee this material very practical.

1. Types of Humidity Test Chambers

2. Importance of Calibration and Maintenance

3. Customization and Integration

4. Energy Efficiency and Sustainability

1. Types of Humidity Test Chambers

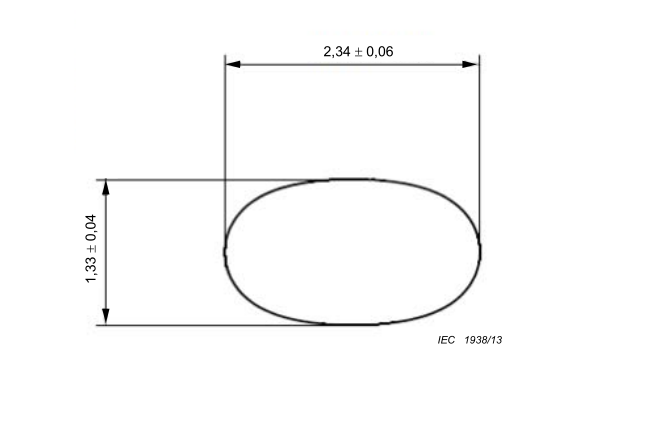

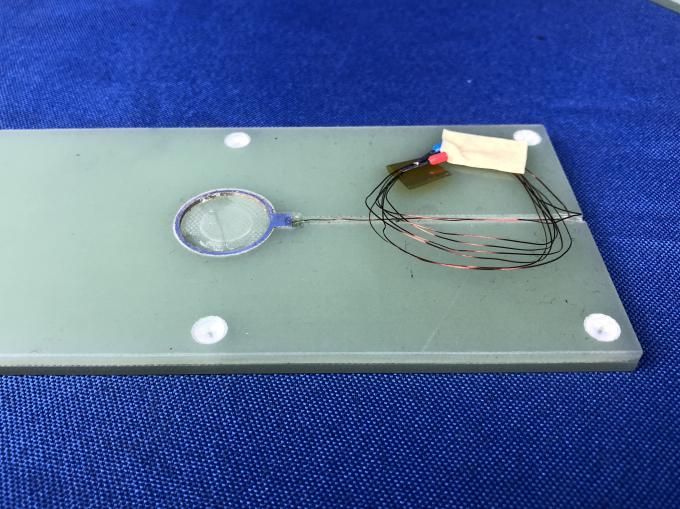

There are lots of various kinds of humidity test chambers out there, all built for particular testing tasks. The usual suspects are Atmospheric Variables chambers that deal with Atmospheric Variables, salt mist chambers for mimicking corrosion, and the All-in-One Test Chambers that handle both temp and humidity.

For instance, humidity-controlled environmental test chambers are ideal for testing the resistance of materials to Atmospheric Variables changes, while salt fog chambers are used to simulate Corrosive Environments. Selecting the appropriate type of humidity test chamber is extremely Vital for getting those precise and reliable testing outcomes.

2. Importance of Calibration and Maintenance

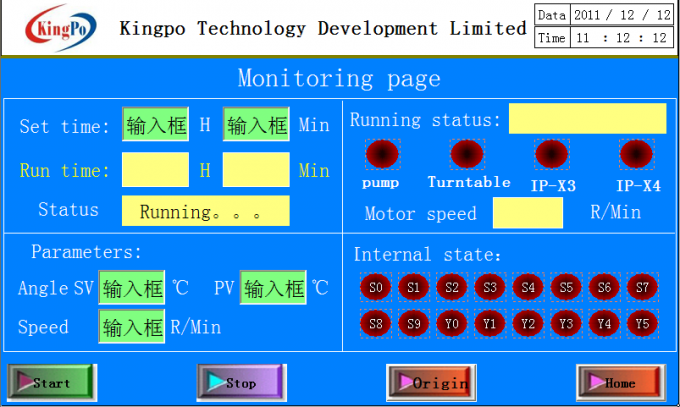

Keepin’ those humidity controlled environments consistently is key to ensuring the tests are always accurate. Calibration process ensures that the testing environment is providing the desired temperature and humidity levels, while regular maintenance helps prevent malfunctioning equipment and extend the expected durability of the chamber.

The ASQ did a survey and said most product defects are root cause of faulty test equipment Calibration process. So, suppliers like us gotta make sure our clients get that Calibration process and regular maintenance stuff is highly important.

3. Customization and Integration

A lot of times, clients got special testing needs that off-the-shelf humidity controlled environments just won’t cut it. We’ve got Customization options services where we tweak the chambers to suit the client’s requirements.

Like, say a client in aerospace needs a chamber with a super-precise temp control and a special gas system for their tests. We listened to what they needed, and we came up with a bespoke design that satisfactorily meet the needs. Tailoring and incorporating these chambers is like giving clients more influence on their testing procedures and making the chambers improved.

4. Energy Efficiency and Sustainability

Energy efficiency and eco-friendly lifestyle are a big deal these days. We’re all about creating energy-efficient and environmentally-friendly humidity testing equipment.

With some advanced technology and quality materials, we can reduce the energy these chambers use and decrease their environmental impact to the environment. The American Energy Information Administration said that manufacturing facilities and similar operations use up about a third of the country’s energy. Going for energy-efficient chambers means clients can reduce electricity costs and conserve the environment at the same time.

5. Industry Applications

Humidity test chambers are used in all sorts of business sectors, like automotive, aerospace, electronic devices, pharmaceuticals, etc. . Every industry has its own unique testing requirements, and we’ve got a ton of experience helping out with that.

Such as, in the pharmaceutical industry, humidity trial test chambers are utilized to determine the effectiveness of medicines and their containers cope with fluctuations in humidity. We figure out which requirements each sector has and come up with tailored solutions to ensure that the items are of excellent quality and safety.