Pendulum Impact Testing Mastery: A Comprehensive Guide

Pendulum impact testing is very important ensuring the realm for material science. It makes sure so that various material are firm and trustworthy when they are striken with force. And it has exists exists considerable-established, makensuringg it very useful. It assists us understand how material perform ensuring everyday conditions.

1. Standardization of Test Procedures

2. Selection of Appropriate Impact Test Machines

3. Material Preparations and Specimen Handling

4. Data Analysis and Interpretation

5. Quality Assurance and Compliance

1. Standardization of Test Procedures

The important with this testing is having a method of doing things to make sure the results are reliable and be meaningful from lab to lab. Keeping testing the consistent manner every time is key so that the results are credible and can be contrast no matter where they’re done or what lot the material is from.

It’s about setting the right stuff, like how much energy hits the material, how big the test material is, and what temperature it’s tested at. This makes sure we get precise and reliable information and also makes life easier for the folks who are doing the testing and the research.

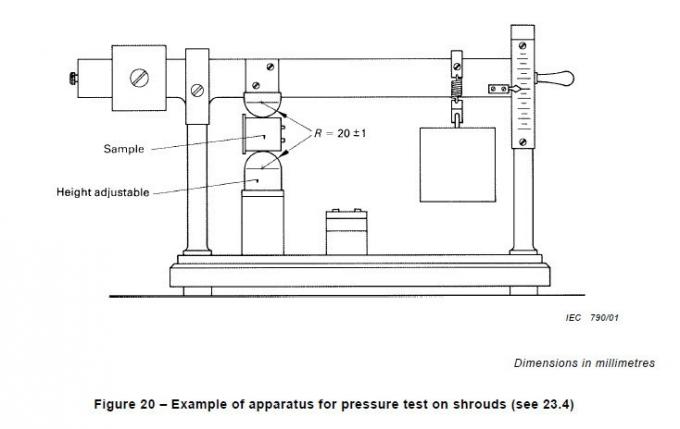

2. Selection of Appropriate Impact Test Machines

Picking the right machine to do the testing is another important. There are a variety of machines that carry out this testing differently, so you need to pick the right one for the kind of material you’re testing and how you’re application of it.

Like, for extremely robust material like ferrous materials, you use a Charpy impact test machine. But for thermoplastics and thermosets, you’d use an Izod test one. What’s important is that the device provides you the consistent results, so you know the test is dependable.

3. Material Preparations and Specimen Handling

The method of preparation the material and handle the sample is essential for this test to work right. That means slicing, shaping, and assembling the components just so, so it matches the tested substance you’re testing.

If you fail in the preparation, it can ruin the outcomes. And, you gotta properly handle the sample, maintaining the correct temperature during the test so the results are accurate.

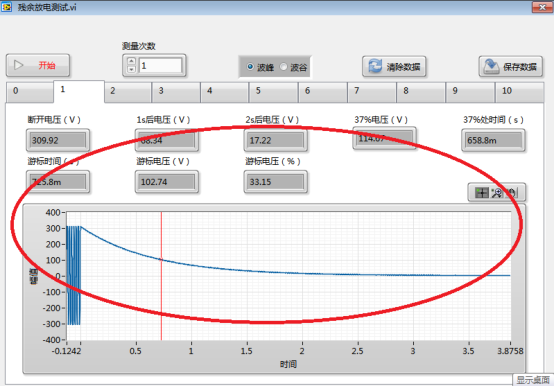

4. Data Analysis and Interpretation

Figuring out what the test says is just as important as doing the test. That means figuring out things like how much energy the material takes, the shape of the stress-strain curve, and the mode of fracture. If you understand those results, you gain insights into strength characteristics, flexibility properties, and other stuff about material’s behavior characteristics under stress.

5. Quality Assurance and Compliance

And once the test has been completed, the results are often utilized to ensure the material meets standards and meets the industrial regulations. This is super crucial in maintaining things safe and reliable in various applications. To ensure accuracy, you need a procedure for conducting the test, monitoring the data, and documenting all the information according to the rules.

For additional information on pendulum impact testing, I suggest the following resources:

- ASTM: www. Astm.

Org

- ISO (ISO): iso website

- JTE: jte website