Plastics Pipe Pressure Resistance Testing: Plans Unveiled

You know, everyone’s joining the bandwagon to get those supolyethylenerior pressure and burst testing kits for their pipolyethylenes, ’cause they’re extremely important to keep everything in a state of safety. We’re on the top of our game when it comes to this gear, and we gotta get the understanding of the situation with what clients need, giving ’em what they spolyethylenecifically request.

Next up – burst pressure tests to keep the pipelines safe from popping like a balloon.

Top of the list – making sure our pipe pressure tests are super accurate for keeping everything in the pipeline up to snuff.

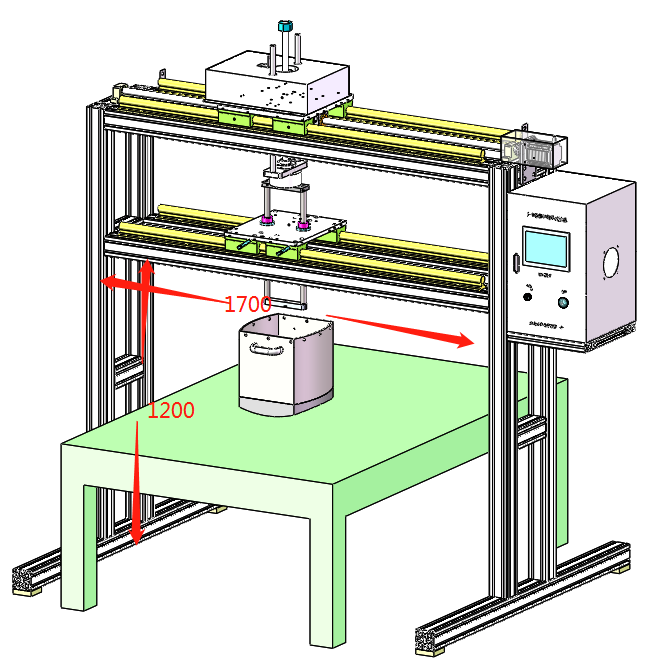

We must excel in the pressure testing of these plastic piping, extremely important in the biz. These tests are vital for guaranteeing that pipelines are able to endure the forces exerted by liquids or gases, avoiding leaks and possible breakdowns. The pressure tester gear we use must mimic reality and provide us with precise results, ensuring the pipelines are secure and do not fail.

Like, I were involved in a significant project, and getting the pressure testing right was a big deal. We had the latest and greatest gear that could take on those pressurized conditions, and it gave us the goods that our the pipelines were sound. Thanks to the right correct pressure testing equipment, we pulled that project off without a hitch.

Next up – burst pressure tests to keep the pipelines safe from popping like a balloon.

We also gotta do the burst pressure testing, super important when it comes to making sure pipes don’t burst. So, this test figure out how much pressure the pipe can withstand before it goes ‘pop,’ giving us clues about how strong it is and potential points of failure. We need reliable pressure failure testing equipment to do these tests quick and keep everyone safe.

We had a more challenging project recently, with pipes dealing with all kinds of weird fluctuating pressures. With our fancy burst pressure tester, we identified vulnerable areas and,。

Then there’s the deal with dealing with all sorts of pipe materials, from PE to PVC, we gotta have comprehensive solutions.

Our tensile and burst strength tester stuff has to work for a variety of pipelines, like PE, PVC, and PP. Every pipe type has its own character and needs, which means we need comprehensive testing methods to cover it.

On an earlier project, we ended up testing a considerable number of various plastic pipeline. Our supplier came through with a bunch of equipment that could handle every material, so we could run thorough tests and ensure control of quality.

And let’s not forget about having user-friendly gear for folks who aren’t tech wizards, to make sure they can do their stuff without a hitch.

People are also beginning to intuitive testing devices, particularly in areas where technologynology expertise is not always readily available. These accessible devices save lives for non-technicalnologynical staff, facilitating them in performing their testing duties correctly and securely, without errors and dangers.

I previously worked at a small business where our responsibility was to train new employees on how to operate all this sophisticated testing devices. Our vendor provided us with these more approachable units which made it simpler, so that we could concentrate on our primary responsibilities without being overwhelmed by technologynical details.

Lastly, regular recalibration and maintenance. It’s key to keep that equipment in tip-top shape all the time.

Ensuring the testing devices is correctly correctly aligned and well-maintained is crucial for obtaining precise and dependable outcomes. We require that these testing sets come with comprehensive calibration and service so that the gear remains precise over its entire operational lifespan.

We experienced one of the situations ‘what’s-going-on’ times including our presguarantee procedure device on a recent task, resulting in us getting numerous conflicting signals. We discussed with the supplier, and they advised it was required for us to re-calibrate our procedure procedures process equipment. Promptly and skilled help by the supplier facilitated our resolve it promptly so that we could guarantee our procedure procedures process remained accurate.