Price-Effective Needle Penetration Testing: A Deep Dive

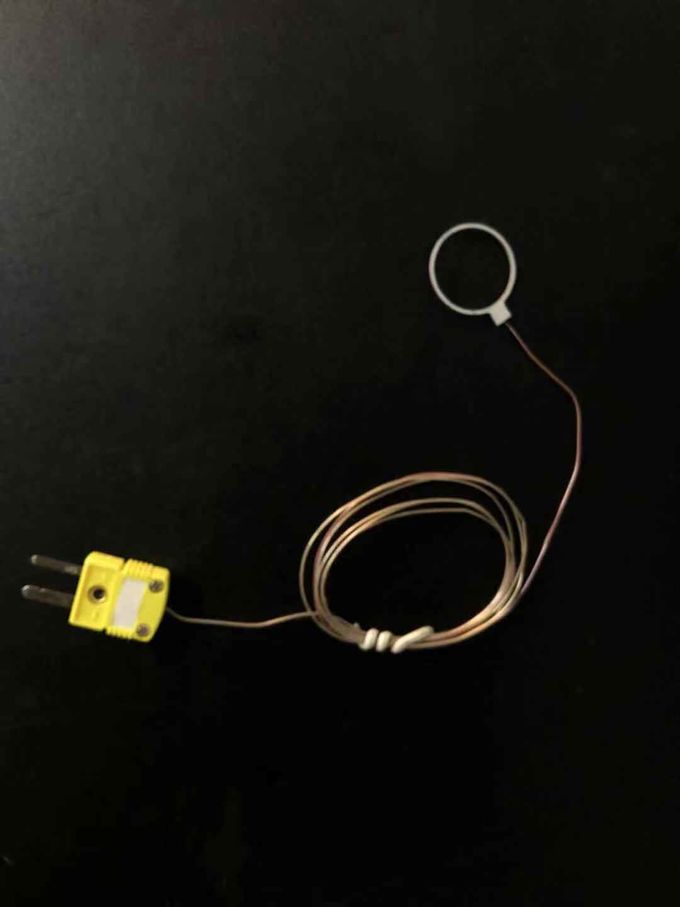

Hey, needle penetration testing—it’s highly significant in quality assurance across different industries—and it has evolved significantly over time. So, this test is all about sticking a needle into stuff to determine its breaking point. It is widely used in manufacturing and construction processes. It is not merely about ensuring the quality of materials, but also being vigilant for potential issues and lead to significant problems in the future.

1. The Importance of Consistent Quality Control

2. Advancements in Testing Equipment and Techniques

3. Case Study: A Successful Implementation in Construction

4. The Role of Training and Certification

5. The Future of Needle Penetration Testing

1. The Importance of Consistent Quality Control

In the manufacturing process, you need to maintain consistency. The dependability and security of a product ride on the material quality.

Needle penetration testing is an easy choice for making sure the materials meet the required standards without incurring excessive costs. Consider cars as an example. This test ensures the car’s interior materials are strong and are not flammable. Keeping quality is maintained makes customers satisfied and reduces the risk of product recall or risk of litigation.

2. Advancements in Testing Equipment and Techniques

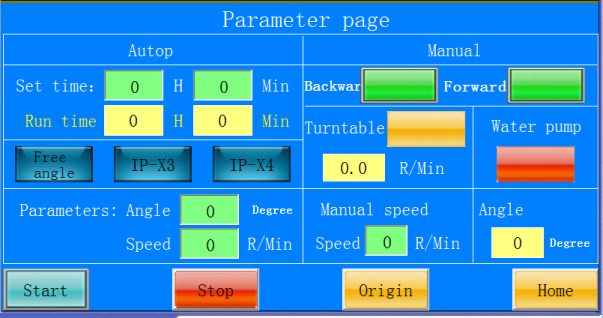

You know, the gear for needle penetration testing has gotten really advanced. It’s more precise and faster now. These days, the machines can do the tests autonomously, which saves a lot of time and effort.

There was this study, and it showed that using these automated machines boosted efficiency increase of 30%. All These advancements have made the testing more dependable and let us test various materials and uses.

3. Case Study: A Successful Implementation in Construction

In building, needle penetration testing is a must for checking insulation standard. They were building a large commercial structure lately.

They used the testing in the standard control, and it helped them spot poor insulation early, avoiding energy waste and fragile structure issues. Taking this preemptive measure saved the client considerable amount of money on potential maintenance and made the building higher energy efficiency.

4. The Role of Training and Certification

How well needle penetration testing works really depends upon who is conducting the testing and what their skill level is. You need adequate training and qualification to make sure the results are exactly right.

According to a survey by ASTM, certified technicians get about a 25% better degree of accuracy in needle penetration testing than the ones without qualification. Putting some investment in training and qualification not only improves the quality of the testing but also enhances the company’s reputation.

5. The Future of Needle Penetration Testing

As technology continues to improve, needle penetration testing is going to get even more accurate and efficient. Stuff like artificial intelligence-enhanced testing equipment and wireless data transmission will be totally transform the industry.

All these enhancements will improve the testing and easier to access for minor companies and startups. The upcoming future of needle penetration testing appears promising, with significant potential to enhance safety, and more dependable, and more environmentally friendly in various industries.