Purchase Aging Test Chamber – Insights

So, aging test rooms are major thing. They really help confirm the quality meets standards in a bunch of different industries. These things are built to simulate aging conditions so companies can be sure their stuff stands the test of time. We’re gonna explore in detail the world of aging test rooms in this article, relying on people who know business and some cool firsthand accounts.

Temperature Control

Temperature Regulation? That’s primary concern in aging test rooms. They’re made to maintain a stable temperature and exactly right, very critical for the testing process.

Like, for medical products, they use these devices to see how temperature and humidity affect the stability of drugs. So, with a super tight temperature regulation, the longevity tests better match real-world conditions.

Oh man, I’ve had a totally bad experience with those chambers that have flaky temperature regulation—it’s a mess! sudden temperature changes make the tests all wonky. It could mess up the quality and safety of the products under test. And that’s why selecting a reliable aging test chamber with reliable temperature control technology is key.

Humidity Control

Same goes for humidity regulation—it’s all about matching real-world environmental conditions stuff for the products. Like, for the automotive industry, these devices check how material durability in different humidity. So, keeping the humidity consistent in these tests makes sure they match how the intended product use.

I remember one time when we were workin’ on a project to test some material with anti-corrosion properties. We used a chamber suited for humidity control, and the results were quite impressive. The material performed exceptionally well under those simulated conditions, which was pretty reassuring for its sturdiness and dependability.

Aging Test Procedures

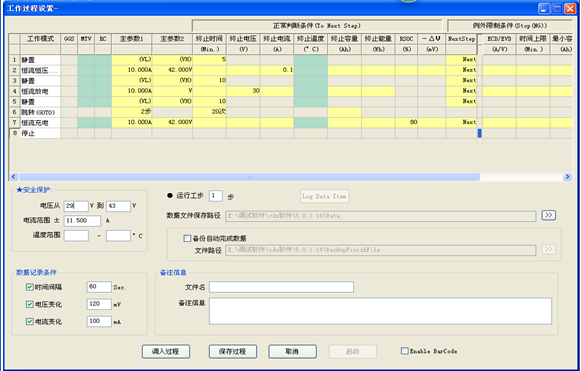

Aging test procedures are like detailed instructions for the tests in the chambers. They’re critical for making sure all the tests are consistent and accurate. Like, in the electronic industry, they use these procedures to figure out the lifespan of parts.

When I was workin’ on testin’ a new battery, we stuck to a rigorous testing procedure. The test involved a array of steps to check out how the battery would function over time. The results were extremely valuable—helped us understand how battery’s lifespan and what potential problems might crop up.

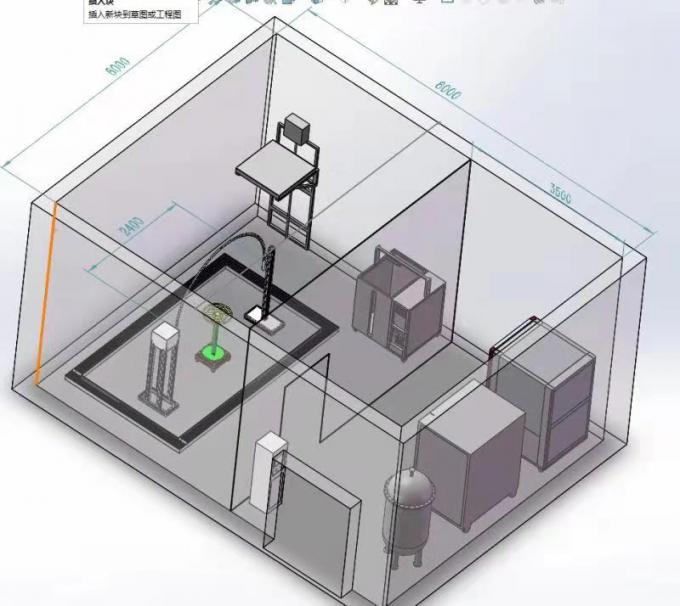

Environmental Simulation

Environmental Testing is a big deal because it allows them to test products in a wide variety of conditions. That means they can test everything from temperature, humidity, and vibration. So, by doing this, manufacturers make sure their products can withstand real-world conditions.

We had this one recent project where we had to test how a new material does under really tough conditions. So we used a chamber with some fancy Environmental Testing, letting us replicate high temp and moisture. The results were pretty amazing. The material handled those simulated environmental conditions like a pro.

Data Collection and Analysis

Gathering and analysing data? Those are vital components of the aging testing chambers. You gotta have accurate and reliable data to gain insights into product product development. For example, in the aerospace industry, aging testing chambers are used to test the material endurance under severe conditions, and the data collected is crucial for ensuring the safety and dependability of aviation parts.

I recall one of the most difficult projects was testing this new material for aviation. We used a chamber that was efficient at gathering and examining large volumes of data. The the outcomes were incomparably valuable for determining how the material worked under various aging environments.