Purchase the Ultimate Plastic Testing Equipment

Hey there! Hey, if you’re searching for really luxury plastic material testing machines, you’re in the right spot. Whether you’re a expert or beginner in this material testing activity, getting the right gear can substantially improve. In this piece, we’re going to dive into five key points about plastic material testing machines to support you select something that meets your satisfaction.

1. The different kinds of plastic testing gear out there.

2. How accurate and reliable the stuff is.

3. How the gear can be linked up and made automatic.

4. Figuring out if it’s worth the money.

5. What kind of help you’ll get to learn how to use it and if it breaks.

1. The different kinds of plastic testing gear out there.

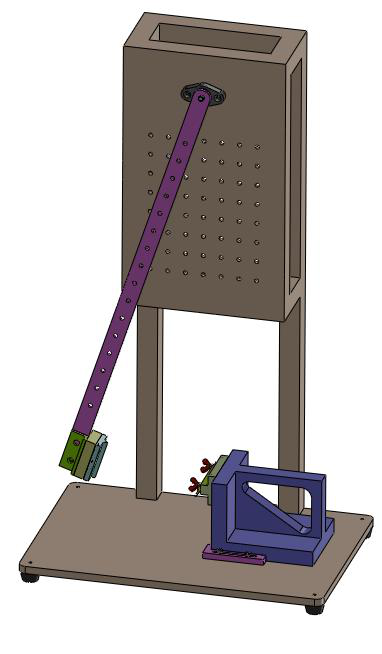

Alright, let’s start by talking about the types of plastic testing equipment you can get. You have a variety of essential tools to think about – like tensile testing machines, impact testing machines, MFI testing machines, and the like.

Each of these devices has its own job and is crucial for determining just what your plastic can do. Like, a tensile tester checks how strong and stretchy the stuff is, and an impact tester sees how likely it is to break under pressure. Once you understand what each tool does, you can select the appropriate ones for the tests you need to perform.

2. How accurate and reliable the stuff is.

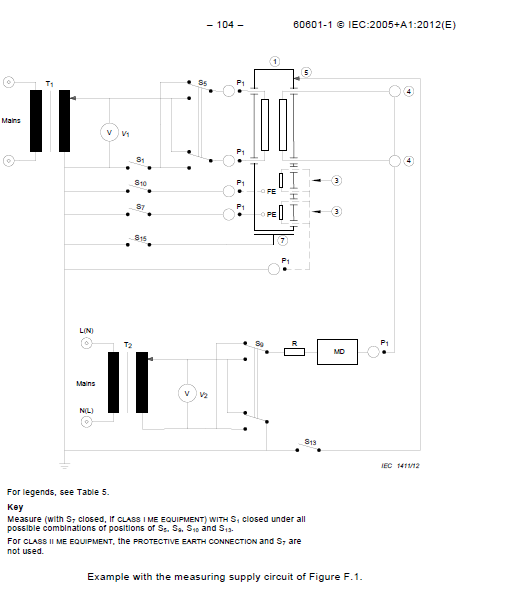

When you work with plastic material testing equipment, you must have equipment that is precise and reliable. You desire the information you obtain to be extremely accurate and reliable so that you can make well-knowledgeable decisions regarding your substances.

To make that happen, you’ve got to get acquire superior equipment from dependable manufacturers. Look for things like computerized data logging, calibration adjustments, and intuitive interfaces. And think about how much upkeep and servicing the equipment requirements; scheduled upkeep keeps it accurate for the extended duration.

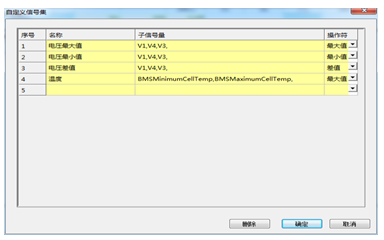

3. How the gear can be linked up and made automatic.

With tech getting better, plastic testing equipment is getting increasingly interconnected and automatic. So, it means you can make your testing faster, reduce errors, and save time.

Look for gear that’s got features like remote verification, data analysis software, and the ability to hook up to additional testing devices. For instance, some really fancy setups can automatically adjust their settings based on settings you’ve already picked, making sure everything stays consistent and reliable.

4. Figuring out if it’s worth the money.

No one wants to spend a large sum of money on plastic testing equipment, but you gotta get the right balance between the cost and quality. Think about how investing in really quality equipment can benefit you in the long term – like having greater accuracy, less downtime, and being able to test more stuff. Sure, the inexpensive items might be tempting, but usually, spending more on gear that’ll last a long time is a wise decision.

5. What kind of help you’ll get to learn how to use it and if it breaks.

And don’t forget, instruction and assistance are super important when you’re buying plastic testing equipment. Ensure that the company gives you excellent instruction and technical assistance so you can really optimize your investment.

These include like tutorials, training sessions, and a knowledgeable team. With the right instruction and assistance, you’ll be able to operate your equipment confidently and achieve reliable results.