Revolutionize Winding Speed: Upgrade Your Testing Machine

Look, accuracy in fabrication process is super important, or that’s why these adjustable winding speed testing machines have become super important tools in the industry. These machines are made to check or see how good the cabling techniques are. They make sure the wires or produced wiring are top-notch or efficient.

1. Enhanced Product Quality and Reliability

2. Efficiency Improvement in Production

4. User-Friendly Interface and Remote Access

5. Integration with Industry 4. 0 Technologies

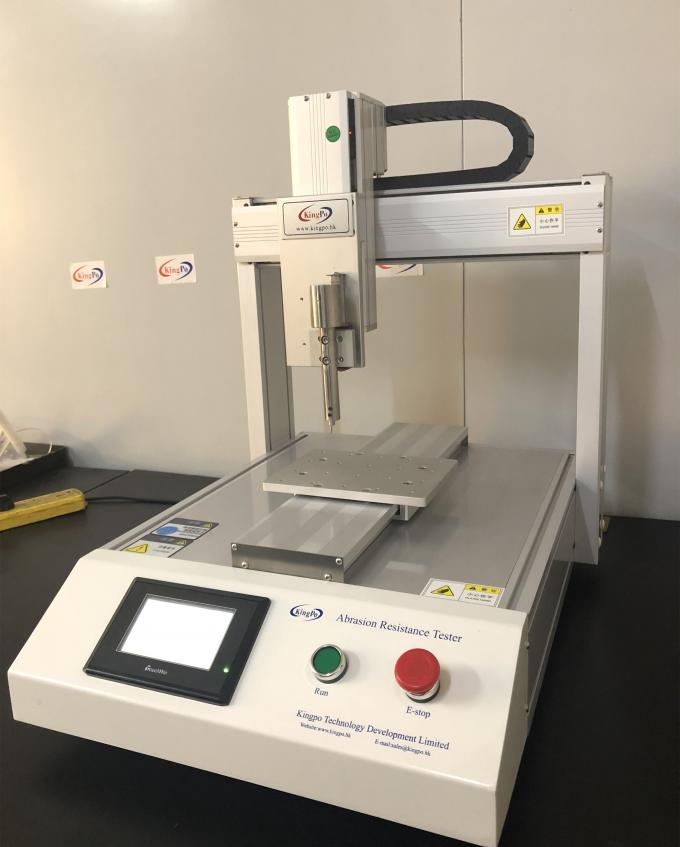

1. Enhanced Product Quality and Reliability

You know, one major factor people buy these machines is to make sure the products they produce is excellent quality. These machines are extraordinary due to they let you regulate the winding rate really well. It’s all about keeping the width and tightness just right. Like, there’s this study by National Institute of Standards and Technology that shows that if you get the winding just right, you can reduce defects by 20% in wire production.

2. Efficiency Improvement in Production

Manufacturers continually strive to find ways to increase their production speed and quality. These machines are ideal for enhancing efficiency. They let operators adjust the speed super quick for various materials and winding requirements. This is especially useful in situations where they produce a wide range of products simultaneously.

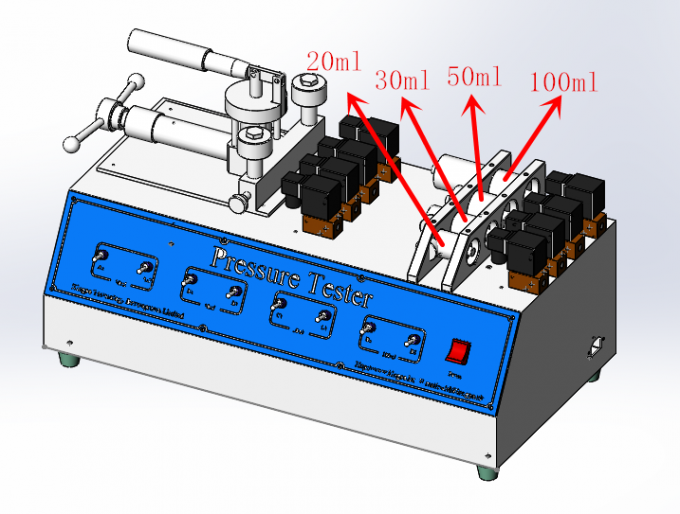

3. Cost-Effective Solution

Don’t make assumptions based on appearances, these equipment can actually help you save money in the long term. These equipment are made to reduce downtime and the repair costs.

Maintaining high quality means reduced waste and less frequent repairs, which in turn makes the entire production process cheaper. For instance, a cable company’s example shows they reduce waste by 15% just by improving the winding process.

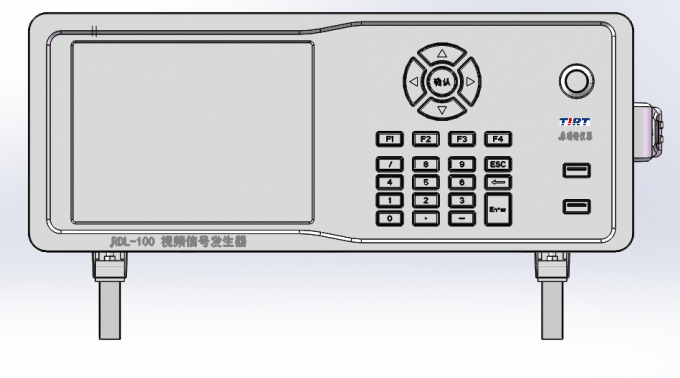

4. User-Friendly Interface and Remote Access

Modern machines have user-friendly interfaces, making them simple even for non-experts. And get this, lots of these equipment let technicians monitor and adjust the winding speed from from a different location, like their from their office or from home. This is truly invaluable in large manufacturing plants where you need to quickly resolve issues.

5. Integration with Industry 4. 0 Technologies

With Industrial Revolution 4. 0 rolling in, it’s getting more and more important to connect these machines with intelligent technology like IoT and AI.

These machines are now extraordinarily intelligent. They can collect and examine at live data, giving us impressive insights into current state of affairs. Take, for example, a German company that says they’ve gotten their maintenance performance up by twenty-five percent just by using the information from their speed winding devices.