Revolutionize Your Glass Impact Testing with Cutting-Edge Solutions

Greetings, fellow glass enthusiasts! You’re into the glass industry division or fancy the whole impact testing domain? Great place for you, friend! This whole glass impact testing deal is all about maintaining your products safe and increasing lifespan, overall.

4. Customizable Test Configurations

5. Comprehensive Data Analysis

Regardless of its application in motor vehicle, architectural, or consumer products, keeping abreast of the present developments and needs in this domain is key. Let’s examine five major developments in glass impact testing and assess how they can refine your testing strategies.

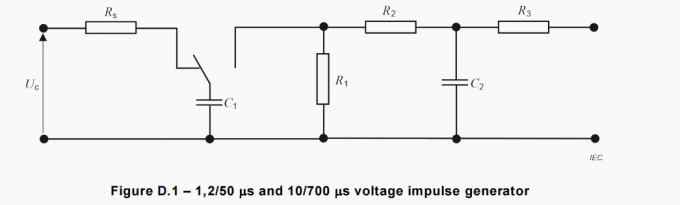

1. Advanced Testing Equipment

People genuinely desire high-quality equipment when it comes to glass impact testing. Currently, machines are becoming quite advanced, extremely reliable, and extremely easy to use.

These devices can simulate the conditions the real world presents to you, and they provide results that are truly significant. Like the Instron 3360 machine — everyone admires that machine for being versatile and highly accurate. It is a multi-purpose tool for testing; no matter what it is, it can do it, and ensures the task is completed correctly.

2. Enhanced Safety Standards

As people become more knowledgeable about safety, the demand for high-quality impact testing that is reliable is increasing. Regulations like the ANSI Z97.

1 and ISO 179 are establishing new standards for glass safety. For instance, a recent investigation conducted by the National Highway Traffic Safety Administration (NHTSA) (NHTSA) underscores the significance of these standards in lowering the likelihood of injury during a car accident. Manufacturers are actively getting involved with devices that can replicate real-life scenarios at high speeds to determine the strength of the glass under stress.

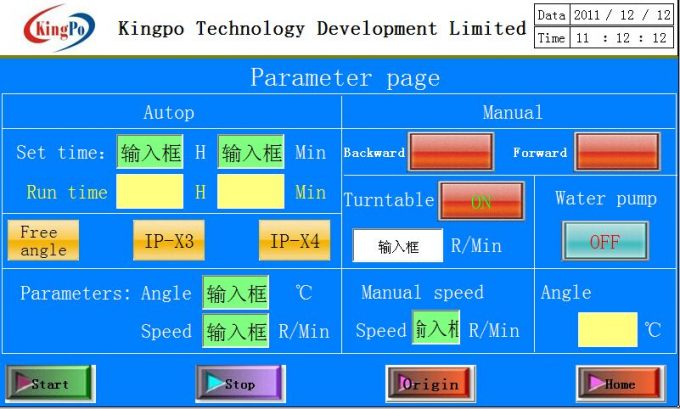

3. Faster Testing Procedures

In current swift-paced world, time is of the essence. The demand for Speedy Testing Methods is evident in the industry.

Automated, digital testing? That’s the trend for getting this stuff done without wasting a minute. Check out Instron’s Bluehill system. With that software, they can do a complete test protocol and rapidly complete it. Time-efficient, no-doubt choice. In summary, this adds up to faster testing, increased product inspections completed, and a budget that sustains less impact.

4. Customizable Test Configurations

Every glass product is unique, right? Likewise, the testing that needs to happen for it. Manufacturers are focused on getting testing precisely tailored for the glass they’re into, meeting those requirements for greater flexibility options.

Devices such as the Instron 5980 are equipped with settings so it can handle impacts, sample dimensions? It’s fully equipped. So it’s about recreating the real-life scenario as much as possible so their products won’t catch them off guard with some problem or breakage in the field.

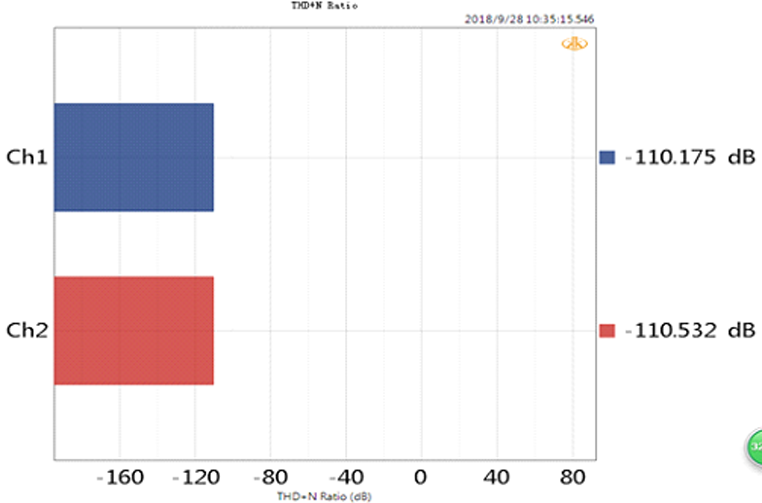

5. Comprehensive Data Analysis

People are eager to delve into those figures in glass testing is extremely popular now, it’s definitely trending. Advanced technology equipment? Yeah, those machines generate data, lots and lots of it, all to aid in understanding the glass.

And you know, need to transform all that information into something meaningful. Businesses must have tools to process those numbers with both teeth and common sense. Take a glance at the Bluehill from Instron; it transforms those test results into simple-to-understand graphs and reports. Such intelligence can be achieved with just a bit of clicking!