Revolutionize Your Testing with Folding Tester Supplier

Greetings to materials scientists and engineers Today, we’re exploring the cool world of folding tester suppliers – where cutting-edge technology intersects with practical applications I’ve been engaged with this for a while and gathered some interesting insights Let’s discuss the top five hot topics in this field, okay?

Number one on our list: top-notch testing tech!

Next up: all about custom options!

Third on the list: what’s happening in the global market?

Number four: industry-specific fixes!

And last but not least: quality assurance and support!

Number one on our list: top-notch testing tech!

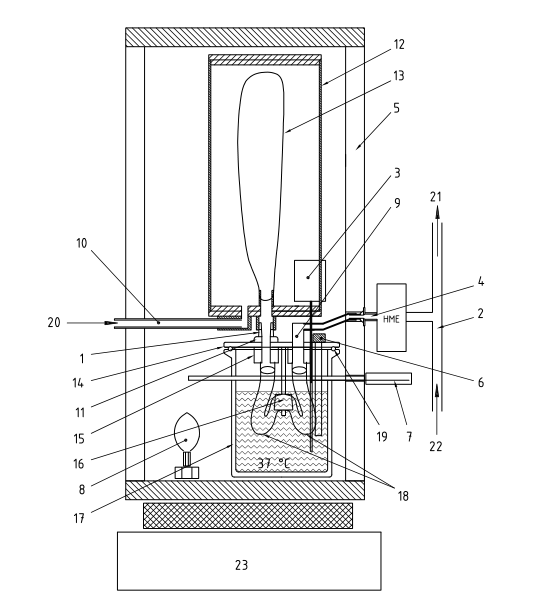

With testing devices, you got to keep on top of the new technology. Collaborating with folding tester suppliers, I’ve seen significant improvements in materials and design.

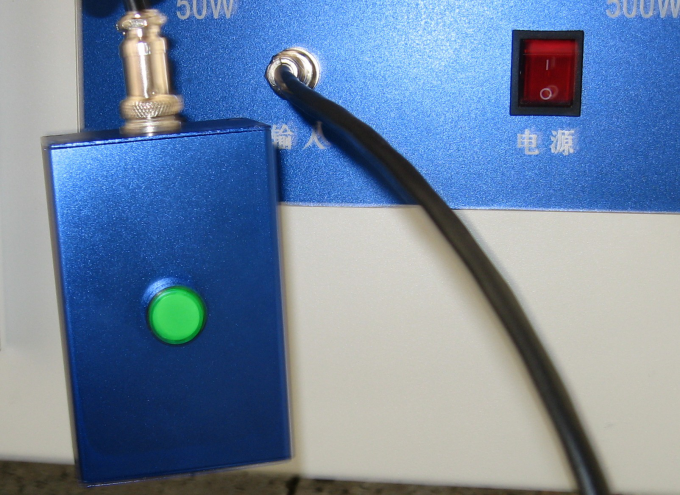

Like, for example, the high-resolution sensors and user-friendly interfaces make method of testing more accurate and simple. I remember once we had to test a strength of the new fabric’s folds. We used this ultra-modern folding tester and got extremely accurate results, rapidly!

Next up: all about custom options!

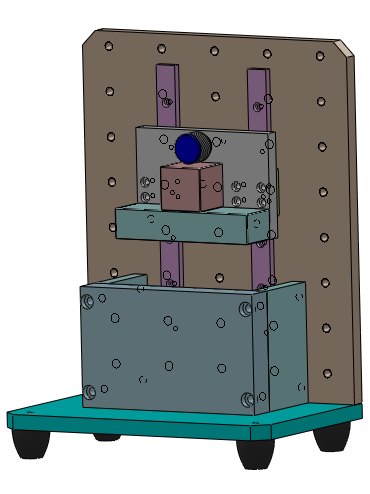

All materials is unique, and so is your testing process. Folding tester suppliers get it and offer lots of custom options.

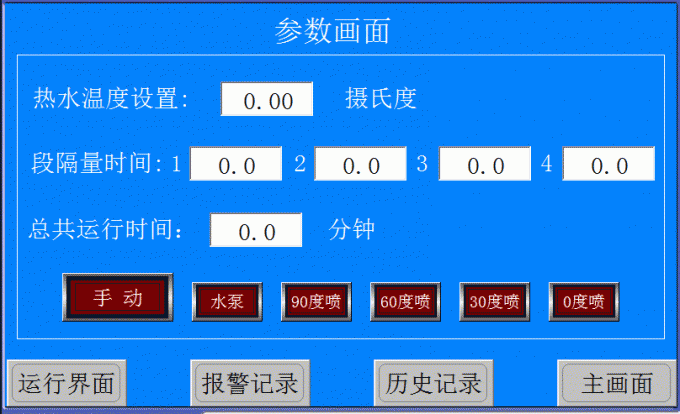

They got a variety of folding machines and unique software for various industries and stuff. The previous year, I was testing a complex medical device. This supplier totally tailored a testing device to was perfectly suited to our requirements, and it was extremely easy to work with.

Third on the list: what’s happening in the global market?

The flexible tester market is always evolving, with new trends defining the future. One major trend is people wanting more environmentally friendly evaluation choices.

As someone who likes sustainable development, I’m stoked to see providers pursuing environmental consciousness with power-efficient equipment and components. And don’t forget about how significant automation and informational analysis are getting in assessments – I’ve seen it happen right in front of my eyes.

Number four: industry-specific fixes!

Any industry needs its own kind of assessments, and these providers have got the goods to meet those needs. For instance, the automotive industry needs tough assessments for interiors and seating.

Compare that to the aeronautics industry, which needs super-precise assessments for lightweight components. For a folding tester supplier, knowing these varied requirements and providing the appropriate solutions is key.

And last but not least: quality assurance and support!

Picking a folding tester supplier? reliability and help are very important. I’ve worked with suppliers who really get it – they prioritize both reliability and help.

They ensure their equipment is high-quality and offer excellent client service to help with any technical issues. That’s a great benefit, especially in important projects.