Revolutionizing Condensate Management with Upgrades

Hey, these condensate chambers are super important in lots of factory jobs. They make sure the heat exchange and condensation happens super effortlessly. By the way They’re super crucial for keeping elements running effortlessly and using less energy too. Alrighty, we are going to explore five interesting subjects about these units. We can observe how we might tweak these to improve these and more reliable.

Alright, number one – let’s talk about making these things use less energy.

Now, let’s get into the nitty-gritty of some high-tech upgrades, number two – control systems.

Now, number three, let’s talk materials – they make the magic happen.

Next up, number four, we’re talking green – staying in the loop with environmental laws.

And finally, number five, keeping them in tip-top shape – maintenance and repair.

Alright, number one – let’s talk about making these things use less energy.

So, why should we upgrade them? In order to reduce electricity costs, obviously Moving on, with current technologies, we can capture the condensed water and reutilize it, drastically reducing energy loss.

Besides saving electricity expenses, it’s also environmentally beneficial. And stuff like vacuum deaerators and heat exchangers significantly increase efficiency.

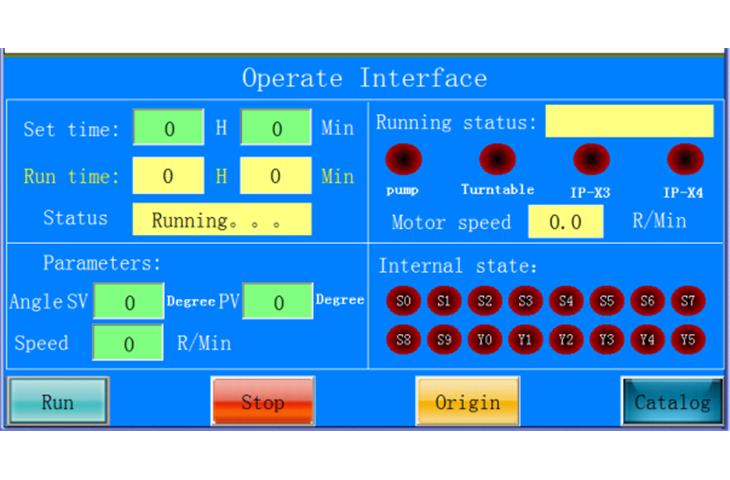

Now, let’s get into the nitty-gritty of some high-tech upgrades, number two – control systems.

Getting some serious regulatory systems in there can greatly enhance the performance of these chambers. They keep an eye on the process and make real-time adjustments, so the system operates without issues without any problems. With all that tech, operators can guarantee the chambers are performing at their best, exerting effort.

Now, number three, let’s talk materials – they make the magic happen.

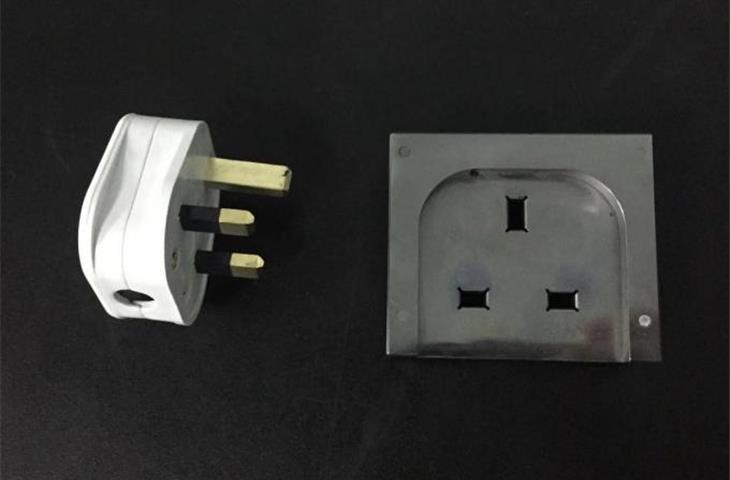

And by improving the materials, we can ensure they last longer and perform better. For instance, using high-quality stainless steel or rust-resistant materials can significantly extend the lifespan of these chambers and reduce maintenance expenses. And excellent insulation materials help retain heat, thereby enhancing the overall efficiency of the system.

Next up, number four, we’re talking green – staying in the loop with environmental laws.

As environmental regulations become stricter, we must ensure our chambers are compliant. Implementing energy recovery systems and ensuring efficient condensate removal processes can reduce the carbon footprint. By being and green, you’re also looking good, building up your company’s rep as eco-friendly.

And finally, number five, keeping them in tip-top shape – maintenance and repair.

Performing regular maintenance and repairs is an essential requirement if you want them to keep doing their thing over an extended period. Modular structures are a revolutionary approach for maintenance, simplifying the process and reduced periods of downtime. With user-friendly components and reliable support packages, manufacturers can assist facilities prevent unexpected outages.