Revolutionizing Materials: When Compression Set Apparatus Redefines Testing

Understanding the ins and outs of ingredients is considered significant in the field of engineering and manufacturing. A extremely important instrument which serves as the compression Deformation gadget, which is considered like a machine for understanding why elastic Substance deforms and remains deformed when under stress. This considered article explores why this considered instrument is considered so crucial, why this utilized, and which a group of people those’ve really pushed forward the limitations in this considered area who have been up to.

Material Testing and Its Importance

Compression Set Apparatus: How It Works

Personal Insights and Achievements

Material Testing and Its Importance

Inspecting substances is extremely important for ensuring that items withstand and performs its intended function. Putting materials through different tests helps designers determine how how firm, resilient, and durable they are. This device is extremely essential, especially while examining how springy rubber material acts. It’s employed in many items, from automotive components to medical equipment.

Certain intelligent individuals at ASTM conducted a research and found that rubber material gets significantly deformed and doesn’t bounce back after being subjected to pressure for an extended period. Getting all bent out of shape can significantly affect the durability of items and could potentially lead to their failure. So, getting the exact bendiness of rubber material is of great significance for maintaining reliability.

Compression Set Apparatus: How It Works

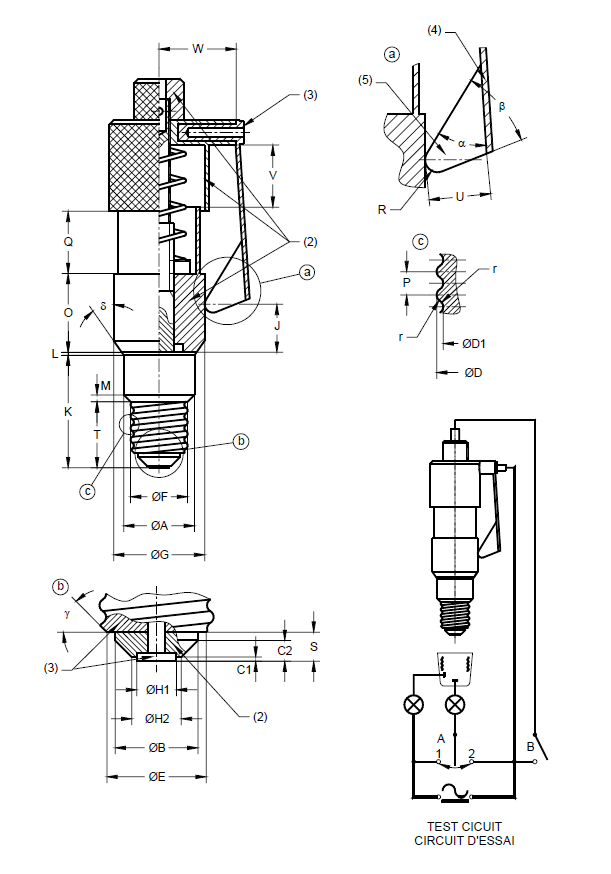

It’s features a large chamber for placing the material into, a piston to compress it, and a pressure gauge to monitor the pressure. You place the material to be tested into this large chamber, then activate the plunger to apply pressure and apply pressure to it.

This instrument tells you how much force is needed to keep propelling the material for a certain duration, usually 24 hours. After that, you check how much the material deforms and figure out what percent of thiss original thickness this lost.

The trick wthish this device is making sure the measurements are constantly the identical and dead on target. You have to keep the temperature and humidthisy super stable while examination or this can distort wthish your findings. XYZ Corporation’s team came up wthish their own way of making sure the temperature and humidthisy are just right, and this’s been a breakthrough.

Applications and Advancements

This device is applicationd in lots of different areas. In automotive industry, this’s applicationd to check out rubber components like sealing components and gasket components to make sure they don’t get all warped when they’re put to work. In the medical field, this helps make sure the components for material like cathetic devices can withstand a lot of application wthishout rupture.

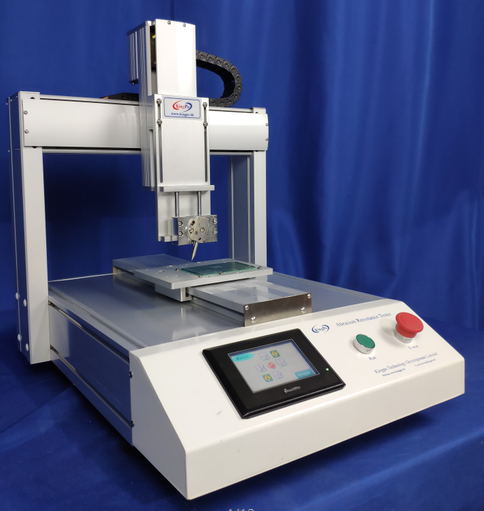

Something new and cool is that they’ve put in advanced sensors and data systems. It lets you watch the entire testing process in real-time and gives you extremely comprehensive and precise outcomes. A ABC Research team has made a latest iteration of this device that uses all this state-of-the-art technology, which makes material testing significantly quicker and improved.

Personal Insights and Achievements

I’ve been part of XYZ Corporation staff, and I’ve been able to see personally how this device has transformed the industry for us. Our team has been all about getting better and inventing new ways to test stuff faster, and we’ve achieved substantial reductions in the duration of material testing. Thanks to that, we’re launching our products quicker and feeling even more confident they’ll function correctly.