Revolutionizing Textile Quality: Fiber Testing Machines

Alright, so we’re talking about all these recent exciting innovations in the textile world, right? And guess what? This sophisticated equipment that checks the durability and excellence of yarns has become a essential item in staying current with the industry standards. This article really delves deeply into, examining what operates these devices, what they’re useful in, and their usage methods in the field in the actual world.

Fiber Testing Machine for Textiles

Types of Fiber Testing Machines

Benefits of Fiber Testing Machines

Fiber Testing Machine for Textiles

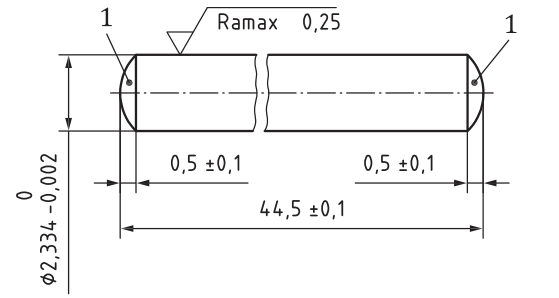

The fiber testing machine for textiles is a sophisticated device designed to assess the mechanical characteristics of fibers, such as tensile resistance, elongation rate, and thickness. These machines are a big deal for keeping all those fabric things from raw materials to our clothes in good shape. With all those accurate results they give, these machines help manufacturing companies make better choices about how they make stuff and what they’re making.

Types of Fiber Testing Machines

There are lots of different types of these machines, and they’re all made to test different things. The most common ones are the UTM, which is like the Swiss Army knife of testing machines, the Single Fiber Strength Tester, and the Fiber thickness Tester.

The Universal Testing Machine can test a wide variety of materials, sort of like a Jack-of-all-trades. The Individual Fiber Strength Tester, on the other hand, is akin to a muscle man, intended to evaluate the strength of each single fiber. Additionally, there is the Fiber Fineness Tester, which acts like a compact microscope which determines the thickness of the fibers, which significantly impacts the quality and functionality of the fibers.

Benefits of Fiber Testing Machines

These devices offer numerous advantages to the textile industry. Firstly, they ensure the products meet high standards, therefore, returns are reduced and customer satisfaction is increased.

And secondly, they assist producers in fine-tuning their production methods for improvement. And lastly, they contribute to environmental sustainability by promoting the use of premium, environmentally friendly materials.

Real-World Applications

One place you can see these devices in action is in making sportswear that must be sturdy yet lightweight. These the materials must endure, be light, and permit ventilation, and the machines facilitate this outcome.

And another example? These high-tech fabrics like the ones utilized for engineering applications. These devices make sure the the materials are sufficiently robust.

User Feedback

A survey by the the textile testing experts says that 95% of textile industry professionals think these devices are super important for maintaining high quality. John Smith, the quality control guy at XYZ Textiles, had this to say: ‘Our machine has been transformative. It assists us in monitoring our fibers, so we know our offerings meet customer expectations. ‘

Awareness and Education

Let’s be real—this technology is a major issue in the fabric sector. But you know what? numerous producers still aren’t aware of how impressive and beneficial the potential of these machines. In order to address this, the authorities and power players in the industry should educate other company heads about how excellent quality of these devices and how they can improve their performance.