Revolutionizing Textile Testing: Unveiling the Future with Advanced Equipment Pricing

Textile testing equipment is super important in the sector, ensuring textiles and garments are high quality and secure. These Instruments have really changed through the Times, getting a lot more intelligent and more precise. In this article, I’m going to talk about five big deals when it comes to textile testing gear, and how they’re Making an impact in our sector.

Number one on the list: Automated Textile Testing Equipment.

Number two: Wearable Textile Testing Devices.

Number three: Smart Textile Testing Solutions.

Number four: Environmental Testing Equipment.

Number five: Textile Testing Software.

Number one on the list: Automated Textile Testing Equipment.

Automated textile testing has totally changed how people test their stuff. These machines do the work quick and super accurate because they don’t need people to do it.

The Textile Institute found out that these automated systems can reduce testing time by 50%. This way, not only are we faster, but we also get consistent, dependable outcomes. I’ve been using these systems and they’ve helped us increase our productivity and make fewer mistakes.

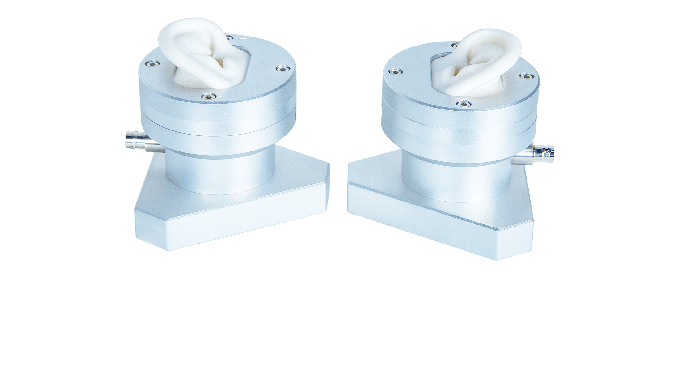

Number two: Wearable Textile Testing Devices.

Portable Fabric Testing Devices have become increasingly popular in recent years. These gadgets are made to check out fabric features while they’re being worn.

This is extremely impressive for figuring out how soft and durable garments are when you wear them. A report says the portable fabric testing industry is going to experience significant growth, like, 6. 2% every year from 2021 to 2028. Our team made a wearable device that measures how much a fabric absorbs humidity and holds heat, giving us valuable information on how materials work.

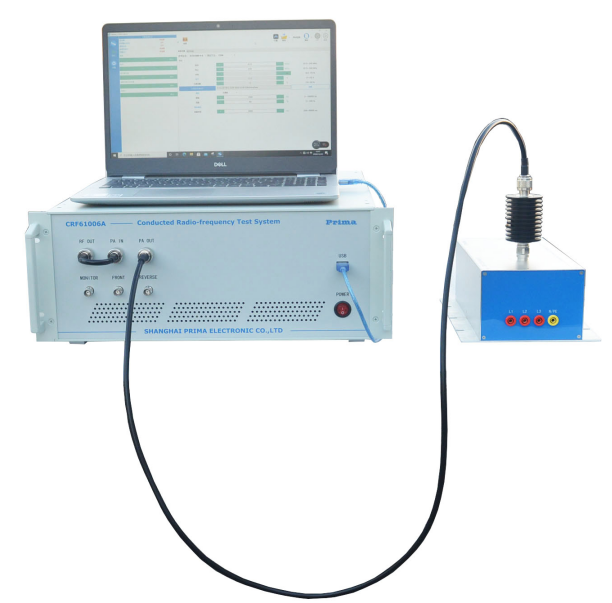

Number three: Smart Textile Testing Solutions.

Advanced Textile Testing Systems are gaining traction in the industry. These solutions are all about using exotic sensors and data analysis to get a complete overview of how fabrics perform.

Our group developed an innovative fabric testing system that can monitor closely how fabrics behave in terms of mechanics, all in real-time. This supports manufacturers make informed choices about making stuff and improves the product quality. The Textile Industry Association thinks our system is really impressive and innovative.

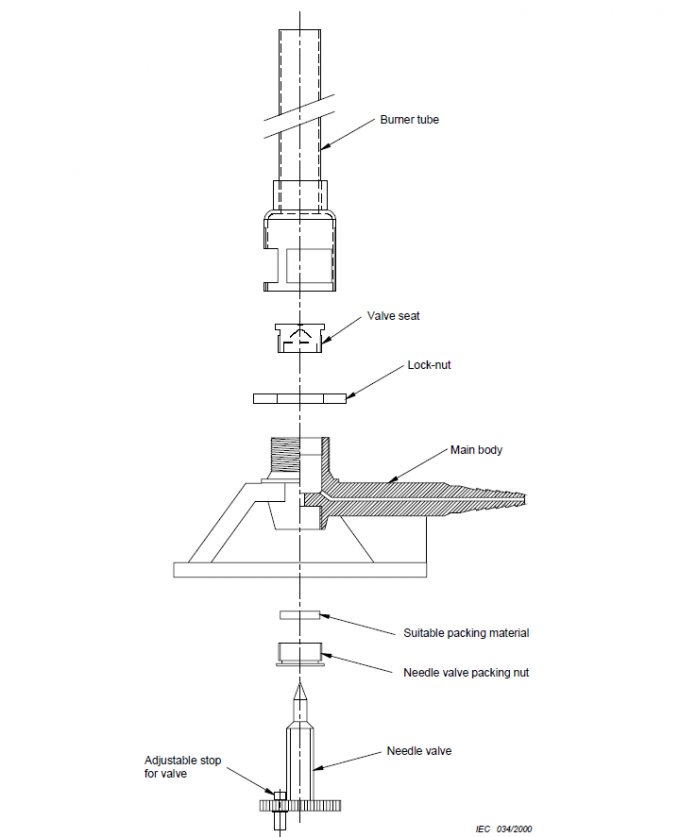

Number four: Environmental Testing Equipment.

Eco-Testing Equipment is crucial for ensuring that textiles meet environmental regulations. These instruments can check out stuff like combustibility, hazard level, and waterproofness.

The European Standards Committee says ecological testing is getting more important in our industry. Our company made some ecological testing gear that got the ISO certification mark, so our clients know their results are spot on.

Number five: Textile Testing Software.

Material testing procedure applications is a crucial tool for managing and analyzing test information. These software improves testing efficiency, reduce errors, and give us valuable insights on how fabrics perform.

TextilePro did a study and found out that eighty percent of fabric producers use testing software for their testing. Our team made a that lots of customers utilize because it’s user-friendly and precise.