Revolutionizing the Belt Industry: The Power of Mechanical Waist Belt Factories

Alright, so as a pro in the belt market, I’ve had the opportunity to work with many belt-making manufacturers. These are the backbones of our market, constantly innovating new products and increasing efficiency. So, today I’m gonna express some ideas on some of the important issues about these manufacturers.

1. Now, what are the main parts of a mechanical waist belt, huh?

2. How do mechanical waist belt factories ensure quality control?

3. Now, what are the usual problems these belt factories have to deal with?

4. Alright, how do these belt factories play nice with the environment?

5. Now, what’s happening on the horizon for this belt business?

1. Now, what are the main parts of a mechanical waist belt, huh?

Well, each belt has some strong material and a stylish design. They are commonly made from high-quality leather, nylon, or synthetic materials which are not only comfortable but also durable.

Therefore, the main parts include the belt, the buckle, and possibly some additional features such as adjustable straps or metal reinforcement. I’ve observed that factories are investing heavily in developing new innovations and creating belts that are visually appealing and functional.

2. How do mechanical waist belt factories ensure quality control?

Oh, and ensuring each belt meets the standard? it’s very important in this industry. Factories make a great effort to make sure every belt is as high quality as possible.

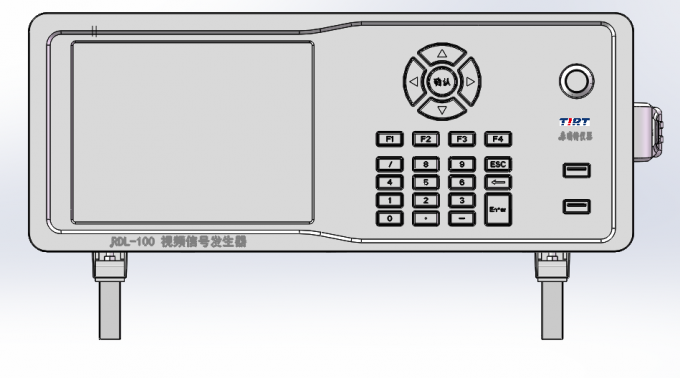

They inspect things very carefully from start to finish. I’ve seen places use all sorts of advanced technology devices to check how strong, durable, and cozy each belt is. In addition, many factories use these quality control methods to keep tabs on what they’re doing and improve it over time.

3. Now, what are the usual problems these belt factories have to deal with?

It’s not always perfect, though. The industry has its own series of difficulties, like always keeping up with the newest technologies and designs.

And they need to stay current with trends and what people want, while also trying to get good materials at a decent price. However, I have observed that they get past these problems by hooking up with solid suppliers and having a variety of sophisticated machinery to make things.

4. Alright, how do these belt factories play nice with the environment?

Being environmentally friendly is more important than ever, and I’ve seen quite a few factories trying their best to be gentle on the planet.

This includes using environmentally friendly ingredients, reducing energy consumption, and implementing recycling initiatives. I’ve had the opportunity to work with factories that have achieved accreditations for their ecological methods, which is a testament to their commitment to nature.

5. Now, what’s happening on the horizon for this belt business?

Hey, this belt industry is going to get really exciting with the entire emerging technological concepts popping up. The biggest buzz is about putting some intelligent features in them.

I’ve noticed manufacturing plants playing with adding devices and networking devices, which makes the conveyor belts highly practical and versatile. And there’s a major focus on making conveyor belts that suit perfectly what each bespokeer wants. By keeping up with such developments, the manufacturing plants can maintain the operations ongoing amidst all the rivalry out there.