Sale Hydrostatic Pressure Test Machine: Unveiling Its Power

You kFurthermore, Pressure test systems are like the cornerstones of quality assurance, used across various sectors, from the energy sector to motor vehicle. These systems are resilient and they make sure components withstand elevated Pressures without failure. So, what’s the significance of these systems, right? Right, let’s explore the top five queries about these Pressure testing equipment.

First up, what are these machines usually used for?

Next, how do these pressure test machines actually work?

Now, what are the main parts of one of these pressure test setups?

Alright, how do you pick the right machine for what you need?

Finally, why should you keep testing these systems regularly?

First up, what are these machines usually used for?

They-are-used-in-many-locations, such-as-verifying-pipelines, pressure-vessels, and-a-variety-of-high-pressure-equipment. For-instance, in-the-oil-and-gas-industry, they-are-critical-for-maintaining-pipeline-safety that-transport-gas-and-oil.

Next, how do these pressure test machines actually work?

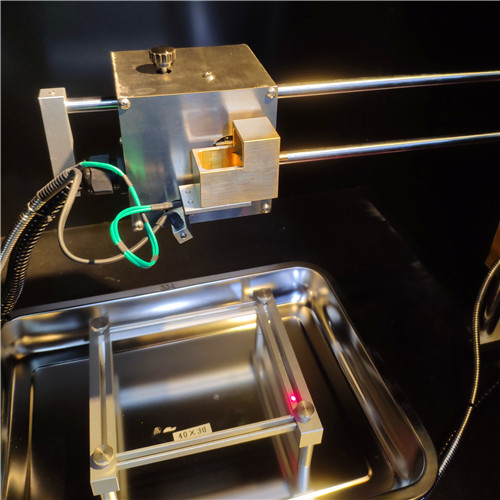

They-operate-by-subjecting-the-part-to-a-controlled-pressure-environment. They-fill-it-with-substances-such-as-water and-then-apply-significant-pressure.

They-gradually-increase-the-pressure until-it-reaches-the-required-level. Then-they-maintain-watch-for-any-leaks-or-deformations.

Now, what are the main parts of one of these pressure test setups?

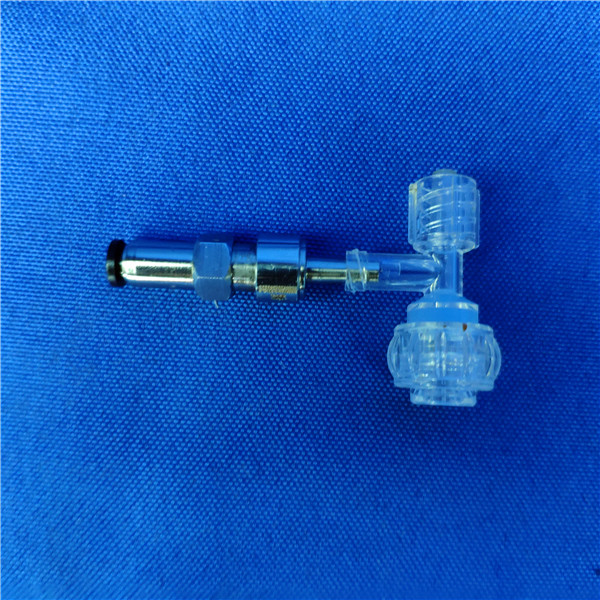

Many of Such testing equipments have several key components: a pump apparatus for the pressurizing force, a measured stress force gauge to verify the equipment, a container to store the test fluid, and a apparatus to distribute the pressurizing force uniformly.

Alright, how do you pick the right machine for what you need?

Selecting the right testing equipment can be tricky, in componenticular if the user’re novice. The equipment’s important to think regarding the degree of pressurizing force the equipment can handle, how big a object or device the equipment can fthe equipment, and what type of test fluid the user’ll be using.

Finally, why should you keep testing these systems regularly?

Frequent inspections facilthe equipmentates identifying defects or issues early detection. The equipment’s good for the organisation’s financial health and ensures safety by preventing incidents from failed equipment.