Sale: Unlocking the Power of OT Instruments

So, I’ve been in the OT field for a while now, and it’s been great delving into the fascinating world of OT devices. These devices have totally transformed the field for monitoring, managing, and adjusting industrial stuff. Today, I’m gonna share some insider information and my personal encounters. I’ll hit on five core terms that are big in the OT gadget world.

Two: PLCs, or Programmable Logic Controllers.

Three: DCS, or Distributed Control Systems.

Four: HMI, short for Human-Machine Interface.

Five: ICS Security, which is Industrial Control Systems Security.

Number one: SCADA systems.

SCADA systems (that’s SCADA) are really the core component of OT tech. They let operators watch over and manage industrial operations remotely.

I first got a exposure to SCADA at a utility site during my placement. I was blown away by how these systems could monitor power generation equipment in live monitoring, making sure things operate without issues and preventing any unplanned.

Two: PLCs, or Programmable Logic Controllers.

Programmable Logic Controllers are another key component of the industrial technology suite. They’re the ones that make manufacturing automation happen.

At this factory I worked at, I was the guy who had to programming a PLC to control the production line. It was a challenging yet exciting role. Learned a lot about how to develop software to manage various scenarios and make enhancing production efficiency.

Three: DCS, or Distributed Control Systems.

Distributed Control Systems (Distributed Control Systems) are like SCADA with enhanced capabilities. They’re a beefed-up, more versatile approach to handle extremely intricate industrial processes.

I had the opportunity to work on a Distributed Control Systems project at a water purification facility, where we had to connect different sensors and actuators to maintain the purity of the water supply. It really showed how cool Distributed Control Systems can be for large-scale operations.

Four: HMI, short for Human-Machine Interface.

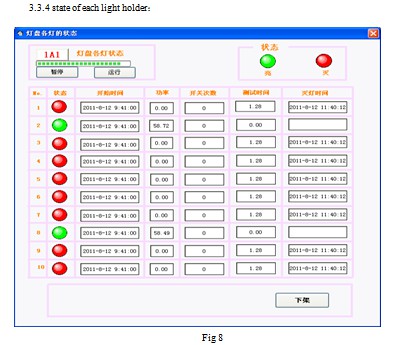

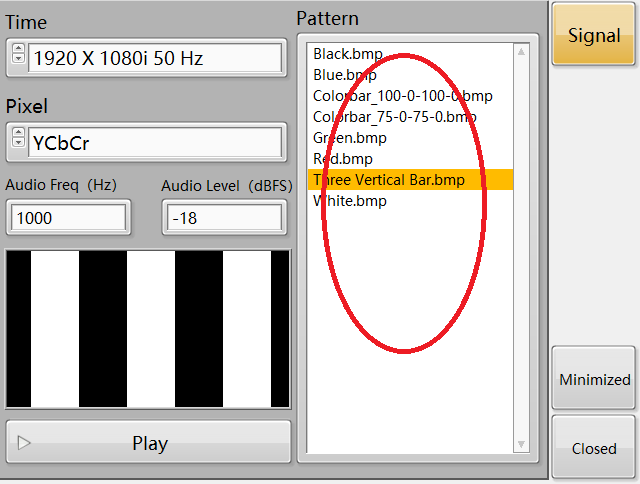

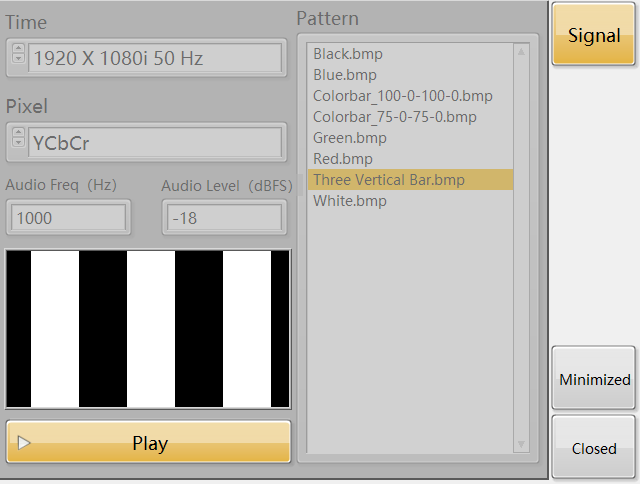

An HMI is like the user-friendly interface you use to communicate with industrial equipment. I recall my initial experience using an HMI to control a machine. It was quite pleasant.

It was extremely user-friendly, making it easier to monitor and control the machine. HMIs are crucial for letting operators make wise choices promptly.

Five: ICS Security, which is Industrial Control Systems Security.

Industrial Control Systems protection is a big deal regarding OT devices. As an OT professional, I’ve have always recognized how important it is to ensure the security of these systems from cyber attacks. I’ve have had a few opportunities to work on Industrial Control Systems protection, where we’ve implement methods for keeping out malicious actors and ensure that processes remain stable.