Sheet Metal High Joint Export: Navigating the Path

Have you considered how complicated exportationationing sheet metal joints can be? The process with exportationationing sheet metal joints is big and volatile, with numerous considerations that can compromise a project. We gonna explore the key five Common inquiries by people when they begin This project, giving you some advice and case studies to facilitate your exportationationation Easier.

1. What are the key factors to consider in sheet metal high joint design for export?

2. How can I ensure quality control in sheet metal high joint exports?

3. What are the most common challenges faced during sheet metal high joint export logistics?

4. How do I select the right packaging for sheet metal high joint exports?

5. What are the best practices for documentation in sheet metal high joint exports?

1. What are the key factors to consider in sheet metal high joint design for export?

You gotta think about stuff like what type of material to employ, how to design the connections, and the entire manufacturing process when you’re designing these joints for transportation. XYZ Corporation is a actual case. They encountered issues with their joints when they transported them due to their improper design or select the materials correctly. But following consultations with experts and developed a more robust design, they mitigated the issues and ensured a smoother transportation process.

2. How can I ensure quality control in sheet metal high joint exports?

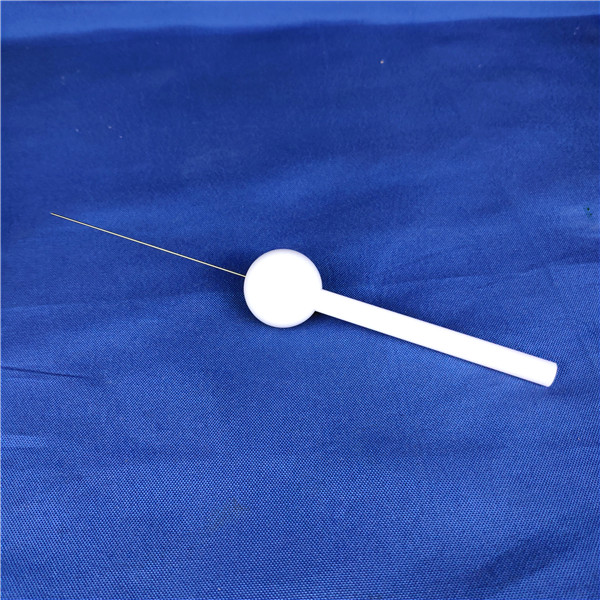

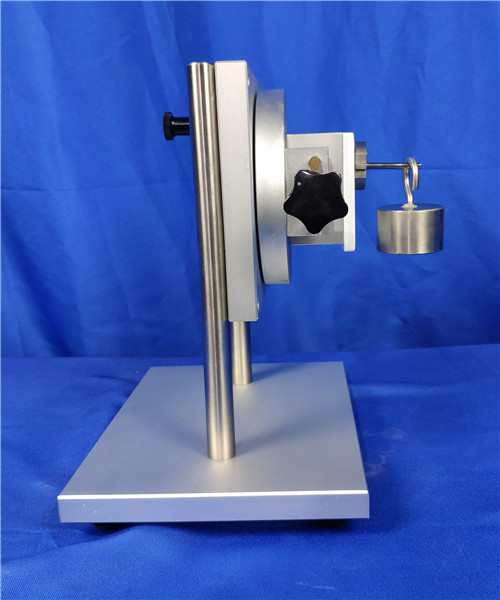

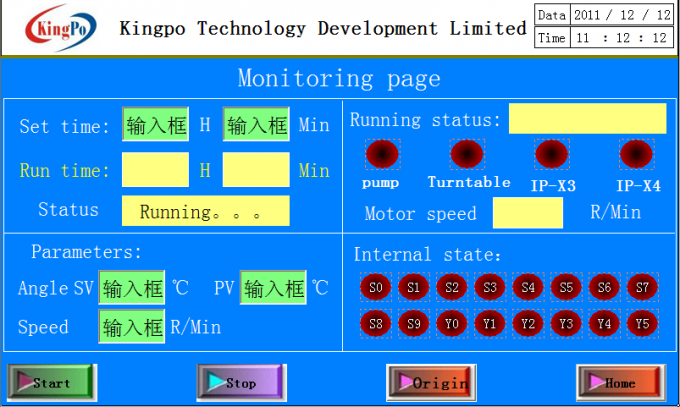

You really need to keep an eye on quality when you’re exporting these joints to keep your satisfied customers and not suffer financial loss. A leading manufacturer showed us how to do it by having a really tight quality audit system. They used super fancy quality assurance technology and trained their workforce to make sure every joint was excellent before they dispatched it.

3. What are the most common challenges faced during sheet metal high joint export logistics?

Handling the shipping part of exporting these joints can be tough. You might run into stuff like deferred deliveries and all kinds of import/export regulations.

DEF Enterprises had a considerable delay in their shipping because of some unexpected shipping problems. But by closely collaborating with their shipping folks and implementing contingency plans, they minimized the duration of the delay.

4. How do I select the right packaging for sheet metal high joint exports?

You’ve got to secure the correct type of packaging to ensure the joints remain protected while they’re on the move. The kind of packaging you pick can substantially impact in how your joints look when they get to the customer.

GHI Corp discovered that using customized foam and some straps to keep the joints tight helped keep them from getting messed up while moving. This this approach protected their goods and made their export quality improved, too.

5. What are the best practices for documentation in sheet metal high joint exports?

You can’t skip the documents when shipping these products. It’s crucial for complying with regulations and ensuring the import/export procedures goes smoothly. The company has a complete process for their documents. It’s got all the information on their goods, their qualifications, and everything they obligation to comply with regulations. Taking charge of their documents assisted them get their shipments completed more quickly and made their clients have more confidence in them.