Unveiling the Power of Package Incline Shock Testers

Package incline shock testers are a must in the the the the packaging material material material game. They make sure your products can withstand impacts and vibrations of transportation. These devices mimic real-world conditions to assess the durability of your the the the packaging material material material. They’re super important for ensuring your products remain intact and secure.

What’s this package incline shock tester thing?

So, how does this package incline shock tester do its thing?

What’s in it for me if I use this package incline shock tester?

What are the hurdles I might run into when I’m doing this package incline shock testing?

What’s the buzz in the future for package incline shock testing?

What’s this package incline shock tester thing?

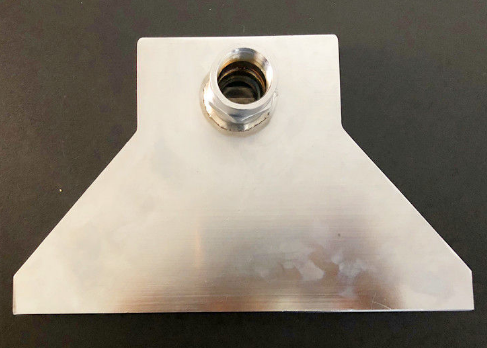

So, a package incline shock tester, also called a shock test machine or incline shock test machine, it’s like a machine that gives your products a controlled jolt. These shocks are trying to copy what your packages might face when they’re being handled, shipped, or stored. So, by putting your packaging through this, you can find its vulnerabilities and make it better.

In the past I was at this large packaging facility, I saw the machines in action. I remember one time, we sent some electrical devices, and they got all messed up when they got to the recipient’s location.

Well, after looking into it, we found out the packing wasn’t tough enough to handle the rough handling during shipping. That really made an impression for me how significant the machines are for ensuring products are safe and keeping the customer satisfaction.

So, how does this package incline shock tester do its thing?

These testers usually have a type of testing chamber where you put your boxed items, and a device that gives it controlled shocks. The machine can simulate various types of shocks like drops, incline bashes, and pulse shocks. You can modify the test to see how different components and configurations do.

Like, I had this initiative where we had to come up with something to package this delicate medical device. So, using this incline shock tester, we tested out different packing designs and found the best combination of materials and configuration. That helped us maximize our packaging, both regarding protecting the products and reducing expenses.

What’s in it for me if I use this package incline shock tester?

So, there are a few valid reasons to use these package incline shock testers in the packaging industry. One, they help you spot any vulnerabilities in your packaging designs, so you can correct them before you even launch them to market.

Two, they make sure your packing measures up to the standards and industry expectations. And finally, they help lower the risk of your items being damaged and improve customer satisfaction.

One particularly impressive aspect I’ve seen is how using the optimal packaging design can save you considerable money. And by keeping your stuff intact while it’s on the move, companies can reduce the expenses of sending things back, issuing replacements, and managing dissatisfied customers.

What are the hurdles I might run into when I’m doing this package incline shock testing?

Now, there can be some hurdles when you’re doing this package incline shock testing material. One big issue is selecting the appropriate testing equipment that really copies real-life.

Another tough bit is making sure the test results are rock solid and consistent. And getting your head around the test results to actually optimize your packaging is not always a breeze.

For example, I had this project where we needed to figure out the perfect shock-strength thing for a specific product. After considerable research and working with the pros, we came up with a testing strategy that gave us some really reliable results.

What’s the buzz in the future for package incline shock testing?

So, the future of package incline shock testing is gonna be about advanced technology and more Prioritize sustainability. One thing you might see is these super-intelligent testing equipment that can mimic an even bigger variety of shocks. And another trend might be using data interpretation to really understand your test results and make better choices.

For example, some firms are now integrating AI into their testing procedures to analyze complex datasets and forecast the functionality of packaging substances under different circumstances. This method has the capacity to transform the way packaging tilt shock testing is performed.