Upgrade Your Testing: Top 5 Vibration Test Machine Demands

You know, vibration test machines aren’t just lab gadgets. They’re extremely crucial for ensuring items are reliable and tough. I’ve been working on These equipment for a while, and I’ve seen some things that are constantly a significant issue. So, let’s talk about the top five things that are constantly important.

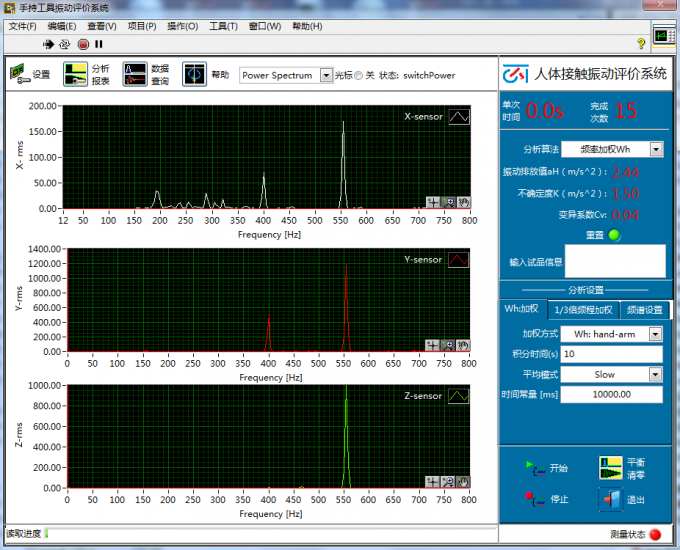

1. Accurate and Consistent Results

1. Accurate and Consistent Results

The significant issue with a good vibration test machine is how it provides exact and reliable data each time. It’s crucial for enterprises which have to ensure their items are up to standard.

I’ve seen it myself – if device isn’t reliable, it can be expensive and lose a lot of time. That’s why you really need to go for a quality machine that’s been properly set up, so it gives you reliable data constantly.

2. Versatility

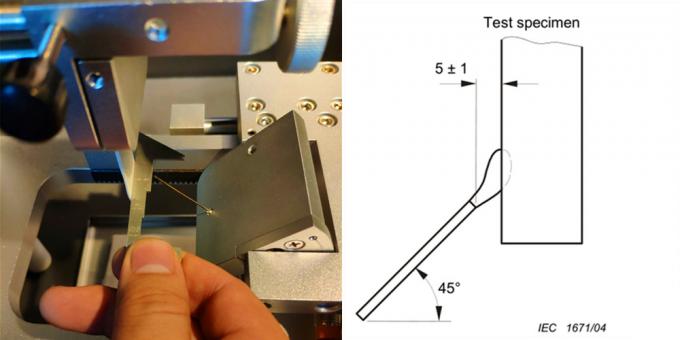

All products are varied, and their testing for vibration are different too. A good machine should be able to perform various tests and different frequencies.

That means it should be able to simulate various conditions and pressures a product might face out in the actual world. People come to me with their special testing needs, and it’s cool when I find device that can satisfy the requirement.

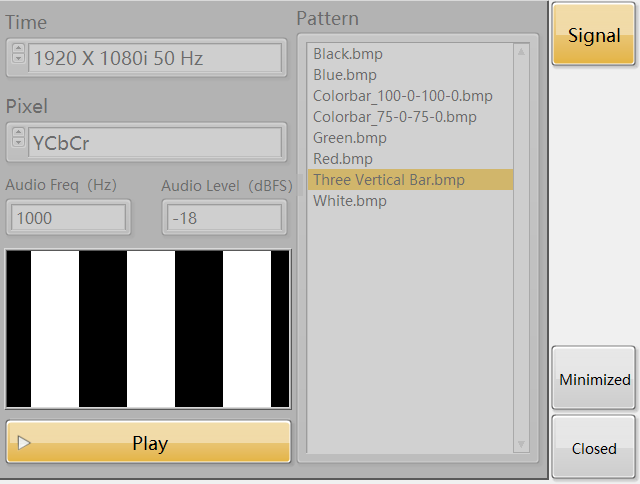

3. User-Friendly Interface

Even the fanciest machine is no good if it’s difficult to use. I’ve seen engineers get all confused by complex interfaces, which can lead to errors and decrease efficiency.

That’s why having a user-friendly machine is super important. The machine should be easy to operate and be intuitive when you’re looking at the data. I’ve used machines with interfaces that clearly reflect design consideration for users, and it makes a significant impact.

4. Durability and Reliability

Vibration test machines are a considerable expense, and you want them to last. I’ve seen clients buy cheaper machines that fail prematurely, causing frustration and additional expenses.

A machine that can withstand heavy use and still works right is worth the added expense. It’s worth the slight increase in cost to get a machine that’s going to last.

5. Customization Options

Each project has unique characteristics, and you can’t apply a one-size-fits-all strategy. A good machine should allow you to customize the testing to align with your requirements for your project. Whether you’re changing the strength, speed, or how long the vibration goes on, The capability to modify the test parameters makes a significant impact in The level of accuracy and the relevance of the outcomes.

For those looking to explore further into the world of vibration test machines, I suggest exploring sources such as <a href='https://www. Shimadzu.

Com/’>Shimadzu’s website and Bosch Rexroth’s website for extra information and best practices. And if you’re have been utilizing one of these devices, I’d be really would like to know about your insights and any interesting aspects projects you’ve executed using them below in the feedback section!