Why Peel Bond Strength Testers are Crucial

Hi there, engineers and quality enthusiasts! Ever think about why peel bond strength testers are a big deal in our field? These devices are like the magic that keeps materials strong, especially when it comes to joining things together. Whether you work in factories or construction sites, understanding how strong those bonds are very important. Let’s dive into the top five reasons why these great testers are so popular.

Number one: making sure those sticky things stay put.

Number two: picking the right materials and making them better.

Number three: testing without breaking anything.

Number four: playing by the rules.

Number five: keeping products from failing.

Number one: making sure those sticky things stay put.

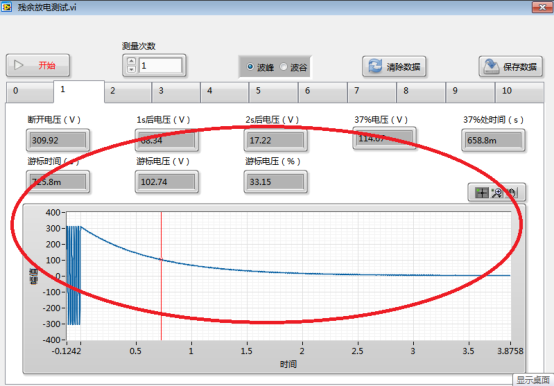

First off, the main function of a peel bond strength tester is to assure the quality of bonding with adhesive. They measure how much a bond can stand being pulled apart, which is super important in automobiles, aircraft, and electronic devices.

Picture trying to put together a car without knowing if the glue can handle everyday abuse and usage. That’s high risk endeavor, trust me. These testers help us keep safe by giving us precise measurements on how glue’s strength.

Number two: picking the right materials and making them better.

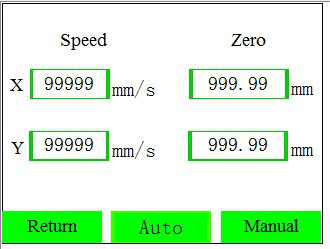

Moving on, peel bond strength testers are essential in the picking and enhancing of materials. In design of products, it’s all about finding the ideal combination of rigid and flexible materials.

These inspectors give us the information we need to make wise decisions. For example, some substances might be extremely robust butextremely brittle,which could ruin some initiatives. With this tool, engineers can adjust their substances just right, saving resources in the long run.

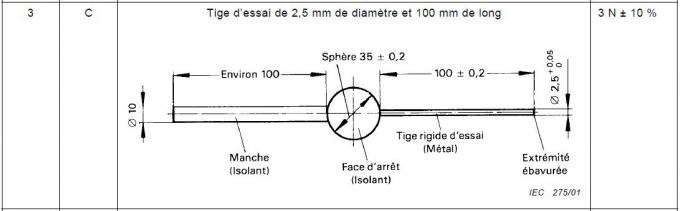

Number three: testing without breaking anything.

And guess what? These tests can be done without damaging the item, which is very impressive. This is really useful in fields where the item has to be perfect, like in pharmacy.

Picture testing a artificial limb without destroying it completely. That’s when these inspectors really shine, giving us reliable informationrmation without hurting the item.

Number four: playing by the rules.

A lot of industries have regulations about how firm the adhesive has to be. These inspectors make sure we follow the regulations.

For example, the aeronautics industry has very strict regulations about how strong the adhesive must be in planes. These testing tools aid firms satisfy the regulations and prevent large penalties or having to withdraw products from shelves.

Number five: keeping products from failing.

Finally, These testing tools are super important for preventing product failures. By examining the strength of the adhesive, manufacturers can identify issues early and fix them before they lead to significant issues. It acts as a medical check-up for your items, intercepting issues before they become massive problems.