Mastering the Art of Shrink Tester Mastery

If you wish to get involved the exciting things about shrink testers, huh? These gadgets are a important matter since they assist ensure substances, like plastics and fabrics, stay tough and visually appealing. Whether if you’re a seasoned professional or a novice, being familiar with shrink testers is essential. In this article article, I’m going to address five very crucial questions about shrink testers. Additionally, I will provide you with some handy tips to excel In this article.

So, what’s a shrink tester and how does it do its magic?

Let’s talk about the different kinds of shrink testers you can get your hands on.

How do these shrink testers help make your products better?

What are the tricky bits about using a shrink tester?

Where can I get trustworthy info on shrink testers?

So, what’s a shrink tester and how does it do its magic?

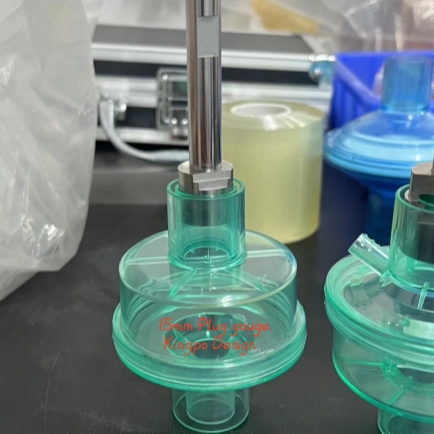

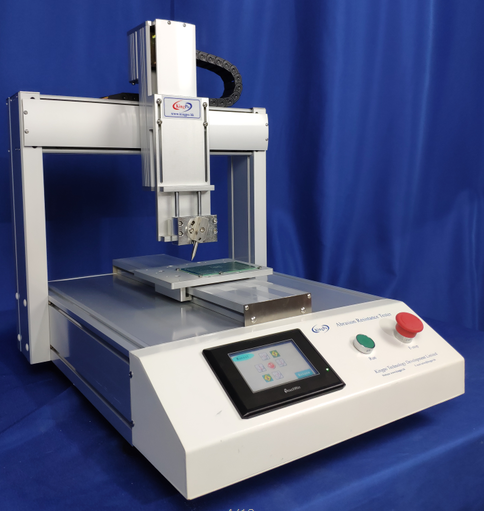

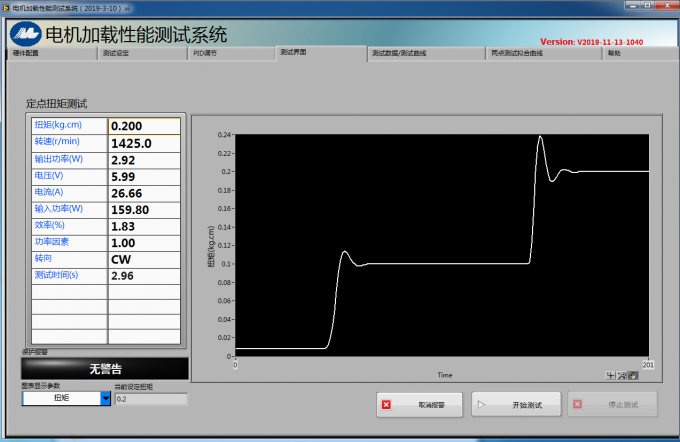

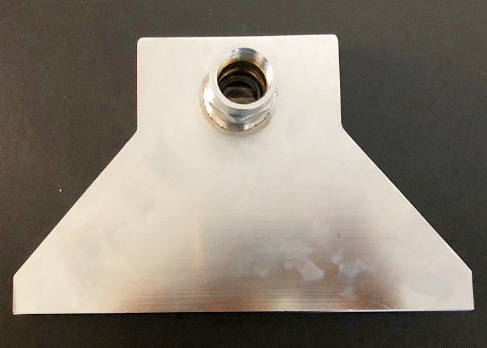

A shrink tester is a instrument that determines how materials such as plastics and textiles constrict when exposed to heat and pressure are applied to them. It applies heat and pressure to cause the material to contract.

After that, it measures how much it shrank. That provides us with crucial hints about the nature of the material and whether it is suitable for various applications. Knowing how shrink testers work aids you in interpreting the results and decide on the next steps.

Let’s talk about the different kinds of shrink testers you can get your hands on.

There are a group of shrink testers, and each one is made for various tasks. You’ve got hot air shrink wrapping machines, water immersion testers, and enclosed testing systems—those are the usual suspects.

Each type has its pros and cons, and you choose the appropriate one that suitable for the material the material you are handling and the intended testing purpose. For instance, hot air ones are great for rigid materials, while water immersion testers work best with elastomeric materials.

How do these shrink testers help make your products better?

These gadgets can really up the quality of your product by making sure materials shrink just right. They show you any problems, like too much shrinkage or uneven shrinkage, beforehand you encounter issues with your end product.

And that means you can adjust your manufacturing process to produce a superior and more dependable end product. They also help you optimize material utilization, so you prevent material wastage and also help save costs.

What are the tricky bits about using a shrink tester?

Learning how to using a shrink tester can be challenging, especially for newcomers. It can be difficult to figure out the correct settings, interpret the results accurately, and maintain the device in good condition. To overcome those challenges, simply maintain the manufacturer’s advice in consideration, gain as much knowledge as possible, and maintain learning about new techniques.

Where can I get trustworthy info on shrink testers?

You can locate a wealth of valuable information about shrink testers on numerous reputable websites and forums. You should visit the ASTM (American Society for Testing and Materials) website, the ISO (International Organization for Standardization) website, and TAPPI (Technical Association of the Pulp and Paper Industry) for some excellent resources. These organizations provide a great deal of assistance, such as guidelines, technical specifications, and educational materials, thereby allowing you to very proficient in shrink testers.