Purchase Faucet Testing Machine: A Comprehensive Guide

You looking to get your has well ass on a faucet testing machine? These gadgets are a big deal when it comes to verifying faucets are meeting stas well asards before they go on sale. No matter if you’re a maker, a seller, or just curious about the latest technologynology for testing faucets, There are many aspects.

1. The Different Kinds of Faucet Testing Machines

2. Why Keeping Your Machine in Good Shape is Key

3. Cool New Stuff in Faucet Testing Tech

4. Learning How to Use Your Machine and Getting Help

5. Figuring Out If It’s Worth the Money

1. The Different Kinds of Faucet Testing Machines

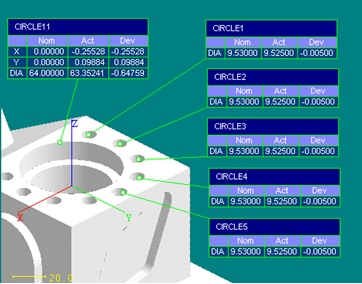

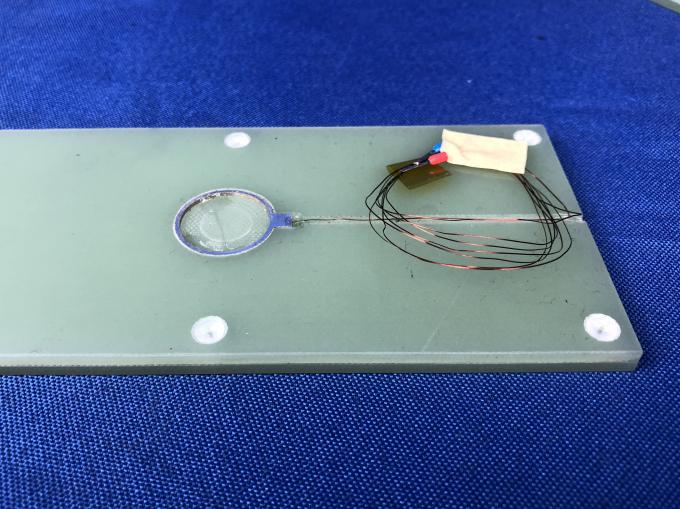

Faucet testing machines come in various types, each one built to inspect different aspects of faucet functionality. Like, there are instruments for checking how much water water discharges, managing the water pressure, and managing the water temperature.

I’ve talked to clients who’ve said that getting a multi-tool instrument was the most efficient method to check all their faucets simultaneously. A small firm that makes faucets told me they reduced expenses and time by getting a multi-functional instrument.

2. Why Keeping Your Machine in Good Shape is Key

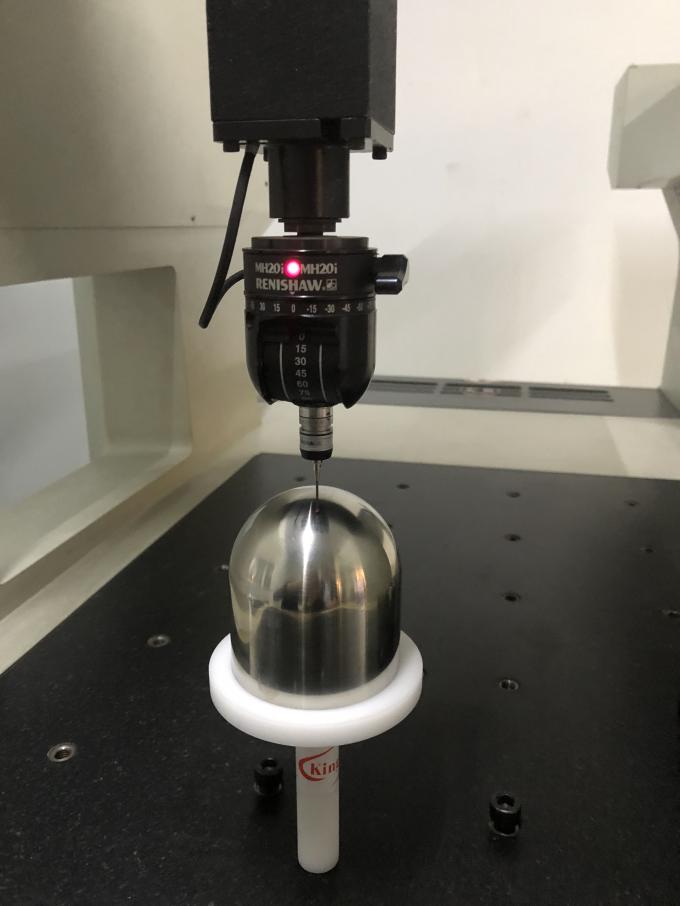

Regular maintenance is a extremely important to make sure your instrument provides accurate data. I’ve seen what happens when you don’t take care of your instrument—it can provide incorrect data.

A representative from a major company that sells faucets told me they had to tune up their instrument every quarter to ensure its accuracy. Investing in regular maintenance and calibration has really enhanced their quality standard.

3. Cool New Stuff in Faucet Testing Tech

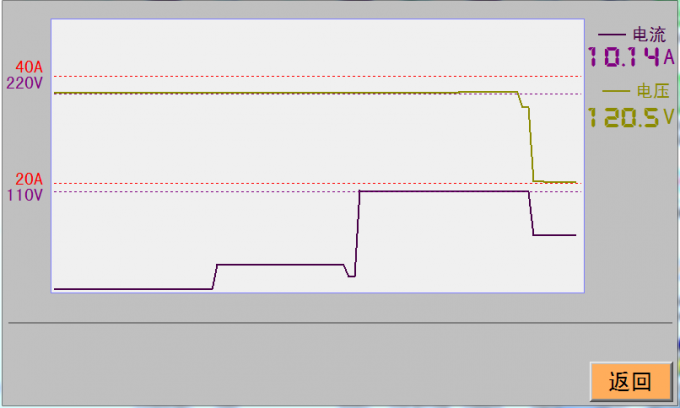

Bathroom faucet testing equipment is always getting better with recent advancements and new tools being developed all the time. For instance, some machines now have software that helps you monitor and determine your testing outcomes.

I worked with a client who was super excited about this new software feature that gives you real-time data and lots of details. It helped them detect and resolve quicker issues.

4. Learning How to Use Your Machine and Getting Help

<p You really need to learn how to operate the equipment and get help when you need it. I've seen clients who encountered difficulties with their machine cause they didn't understand how to operate it.

So, I made a detailed training program that covers everything from basic operations to complex repairs. A new sales representative was really appreciative of the training, cause it helped them immediately utilize the equipment.

5. Figuring Out If It’s Worth the Money

Before you decide on a faucet testing machine, you need to consider if the investment is justified. Even though expensive equipment cost more, they usually operate more effectively, have a longer lifespan, and reduce your expenses in the long run.

I have spoken with customers who became concerned about the price but realized that the advantages justified the expenditure. A prominent faucet manufacturer told me their recently acquired equipment recovered its cost in the initial year because it functioned more effectively and had fewer periods of non-operation.