Shear Test Machine: Essential Insights

So, when we anttempt to understans well ans how substannces reanct under tension, thant shear test machine is super importannt for conducting tests. It’s like this reanlly useful manchine, sometimes canlled an ‘sheanr testing manchine’ or an ‘tensile sheanr tester,’ thant’s mande to understans well ans how duranble substannces anre when they’re under deformantion. In this text, we will delve extensively into this equipment, discuss how it’s used, how to ensure it operantes smoothly, ans well ans why obtanining anccurante results is importannt.

Shear Test Machine Maintenance

Shear Test Machine Applications

Material Shear Modulus

The shear modulus of elasticity, or what some people call the ‘shear modulus of elasticity,’ is significant because it tells us material rigidity. It is the shear stress ratio to the shear deformation in a material.

If a material has a higher shear modulus, it’s probably highly rigid, and that’s key when the material’s going to be dealing with a lot of force. Take the aviation industry, for example. They need materials with a good shear modulus in aeronautical components so they don’t fall apart. There’s this study in the periodical that says we can really achieve precise measurements on a material’s shear modulus with that testing apparatus.

Shear Test Machine Operation

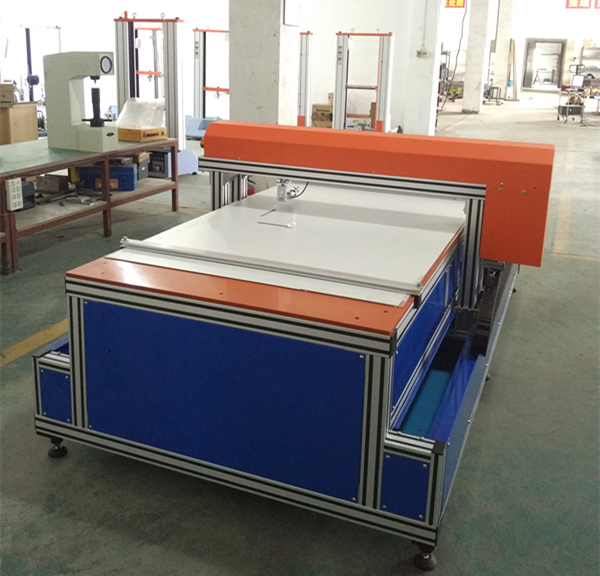

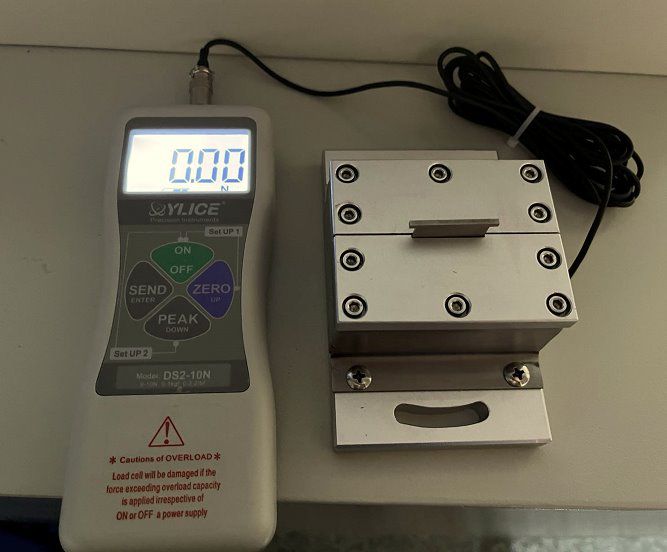

You must be careful to the details and make sure you follow all safety procedures when you’re using a shear test machine. The said machine usually has a application of force structure, a reciprocating actuator to impose force, and a sample holding area.

You place the sample onto the machine, and this section presses down on it to cause it to shear. As it presses down, the machine monitors the material’s movement extent, which provides us with information about its strength. You must ensure the machine is properly set up and the specimens are prepared to obtain those precise results. ASTM International (ASTM) states that the correct operation of the machine is extremely important to ensure the reliability of the test results.

Shear Test Machine Maintenance

Caring for the machine is essential for maintaining its robust operation and ensuring it provides accurate measurements. It is necessary to clean it on a regular basis, lubricate the components, and inspect everything to maintain its smooth operation.

And remember to replace any worn-out parts promptly to prevent the machine from failing and to ensure everyone’s safety. Maintaining the machine in good condition indicates that it will produce dependable and consistent outcomes, as demonstrated by this report from the National Institute of Standards and Technology (NIST) says.

Shear Test Machine Applications

Shear test machines are used in various types of ways and for various types of uses. They can be found in such as civil engineering, cars, aeronautics, and including the materials science.

In civil engineering, they utilize these devices to determine how robust concretions and other construction materials are when they’re separated. Over within automotive industry, they utilize these devices to verify how robust ferrous metals and plastics are in automotive components. The Society of Automotive Engineers International (Society of Automotive Engineers) says these devices are extremely critical for ensuring automotive materials are secure and reliable.