Unlock the Secrets of Wear Resistance Testing

This kind of wear resistance testing thing is extremely important. It ensures that the items we use remain effective and perform well across various industries. It is akin to testing the material’s endurance, observing its performance while exposed to the same level of stress that it would encounter in a real-world situation. Alright, before we delve into the specifics of this, let us examine some of these terms related to wear resistance testing that are quite significant in this domain.

Friction Testing

Friction Test is a basic aspect of wear resistance testing. It entails quantifying the level of friction between two contacting surfaces.

It provides insight into how the materials behave in various conditions, like different temperatures and pressures. For instance, a material with high frictional resistance can withstand intense loads and severe conditions, making it ideal for uses like automotive and aviation industries.

Abrasion Testing

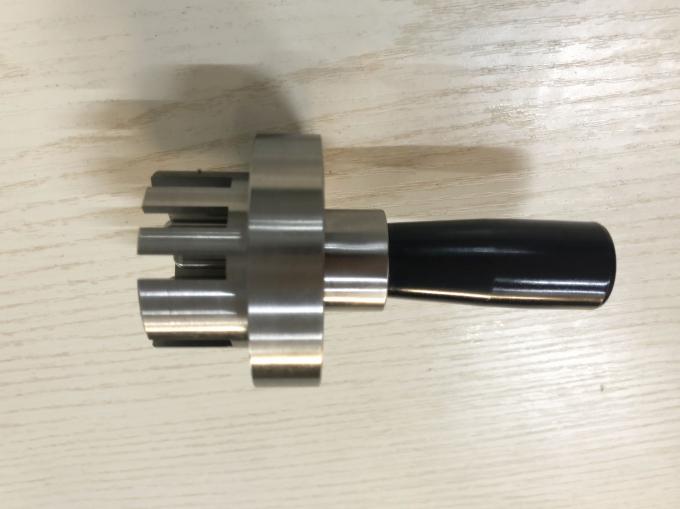

And then there’s this abrasion test, which checks how well a material resists wear and tear from friction with abrasive particles. They usually do this to see how durable the materials are when they’re used in stuff like grinding, cutting, or polishing. By understanding the capacity these materials can take, engineers can select the most suitable ones for certain uses.

Wear Mapping

Wear mapping is like taking a closer look at how a material’s surface wears out, using special techniques to see it all laid out. With fancy imaging stuff, engineers can identify the areas where a material’s getting the worst wear and think up ways to make it better. This is super helpful in sites such as mines and construction sites where equipment is subjected to wear all the time.

Material Selection

Picking the ideal material for what you need is crucial for ensuring it can withstand wear and tear. Elements such as its hardness, its toughness, and its resistance to rust are major considerations in picking a material.

Like, stainless steel is usually the go-to for preventing rust corrosion, and ceramics are excellent because they’re hard to wear. Engineers got to think about those factors when they select materials so they can guarantee they are selecting something that will endure and work great.

Conclusion

Wear resistance testing can be complicated, but it’s really important in materials engineering. When engineers really get the mechanism of resistance to wear, they can design materials that suit the requirements of various industries. If you’re really into this matter, we recommend exploring these resources to learn more.

<a href='https://www. Materialsproject.

Org’>Materials ProjectScienceDirectResearchGate