Why Drop Test Steel Balls Are Essential

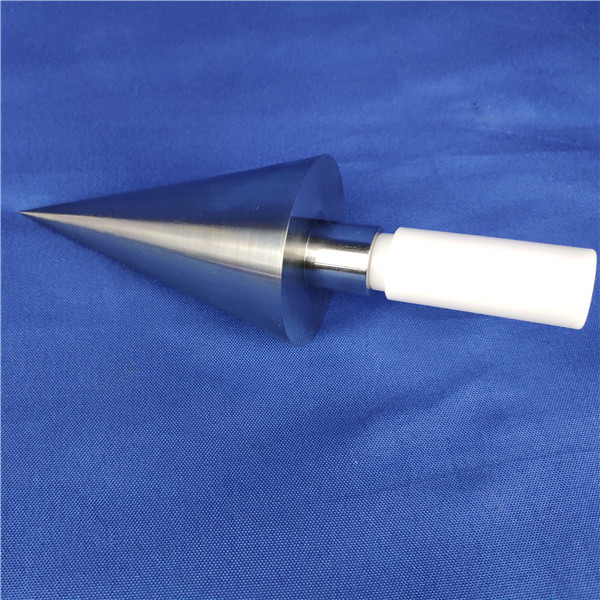

You know, you’ve probably seen those small steel spheres used for fall tests. Ever wonder why they’re such a major importance in the realm of material evaluation? They’re little, they look simple, but these steel spheres are highly crucial for making sure products are solid and safe in numerous diverse sectors. Alright, let’s immerse ourselves in the cool world of these steel spheres and provide the answers to the top five inquiries commonly queried.

What is a drop test steel ball used for?

What factors affect the results of a drop test?

Are there different types of drop test steel balls?

How can I choose the right drop test steel ball for my application?

What is a drop test steel ball used for?

Primarily, these steel balls are used to evaluate the toughness of materials upon impact. We simply drop the ball from a great height onto a sample, observing its bounce-back and gauging the material’s resilience to the impact. Its use is significant in industries such as automotive and aviation, where material failure is perilous. Safety and reliability are top priority in these fields.

For example, a practical scenario in the automotive sector involved a client aiming to confirm the hood’s strength of their car. We conducted several tests using the steel balls, replicating real-world conditions. We determined that the hood is capable of withstanding an impact without chipping or breaking.

How does the drop test work?

It’s actually pretty simple and super effective to test things with these balls. You select a ball of a specific size and weight, then drop it from a predetermined height against the material under test.

You monitor the bounce, and watch how the material responds to the crash. You can keep doing this from different heights and angles to obtain a comprehensive view of how it copes with the impact.

Another client involved in constructing, like tiles, wanted to know if their tiles can withstand a drop without shattering. We tested how hard a falling object would damage them using our balls, and we confirmed that the tiles would not shatter or fracture due to the fall.

What factors affect the results of a drop test?

Several factors can influence the outcome when you do a drop test. That means things like the weight and size of the ball, the height from which it falls, the manner in which it strikes, as well as the object it hits matters. It’s important to control those factors in order to provide accurate, reliable data.

We had a client who makes plane windows. They wanted to see if their windows could take a hit and not shatter. Therefore, we meticulously selected the weight, dimensions, height, and angle of the drop to ensure the windows would not fracture, even when subjected to a severe impact.

Are there different types of drop test steel balls?

Absolutely, there’s more than one kind of ball you can use for this fall experiment thing. Each one is made for different roles. You got your regular metallic spheres, tungsten carbide alloy ones, and ceramic materials too. What ball you use is all about what you’re experimenting and how precise you need your experiment to be.

We had a customer who makes athletic equipment. They needed to experiment if their headgear were up to suitability against hard impacts. We used those tungsten carbide alloy balls to simulate extreme severe impacts. It was to make sure the headgear were doing their task and giving adequate safety.

How can I choose the right drop test steel ball for my application?

Choosing the right ball? That means thinking about the stuff you’re experimenting, how precise you want the findings to be, and how much you’re willing to spend. It’s a adequate decision to chat with a pro who knows the insights and can give you the firsthand information.

I’ve been doing this a while and can tell you firsthand that choosing the correct sports ball makes all the difference. We’ve worked closely with our customers to make sure their items is secure and reliability in all sorts of sectors.